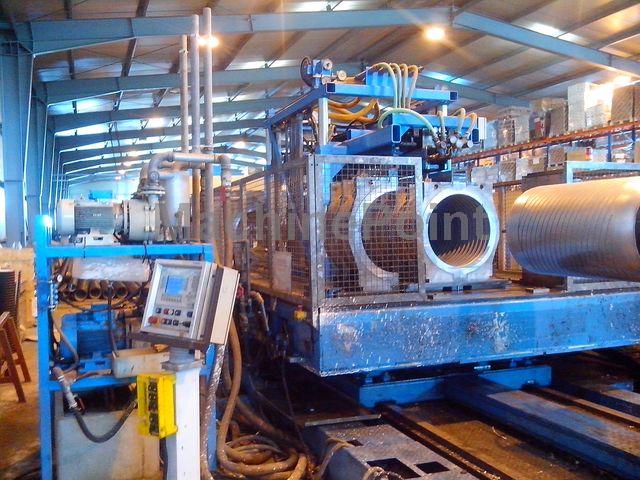

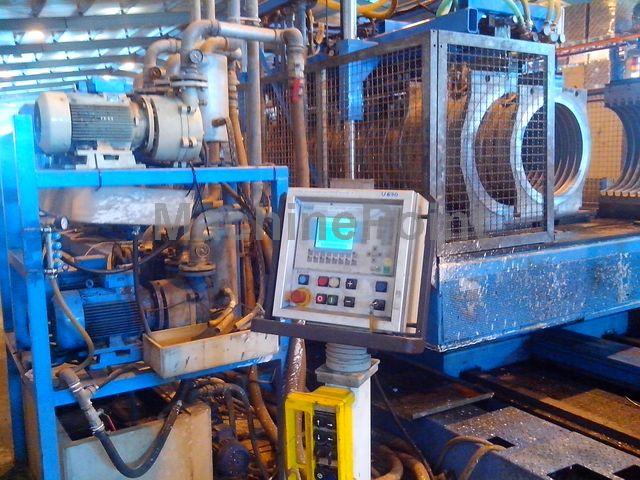

Używana UNICOR UC 1000/9 iV 2000 na sprzedaż

Linia do wytłaczania rur korugowanych UNICOR, MachinePoint oferuje swoim klientom wszystkie usługi niezbędne do zakupu maszyny: transport, demontaż i porady prawne.

Dane techniczne maszyny używanej UNICOR UC 1000/9 iV

Ref.: 300033840

Rok: 2000

Marka: UNICOR

Dostępność: Od daty

Zapytaj o cenę maszyny Chcesz sprzedać swoją maszynę?

Specyfikacja techniczna:

- Maksymalna Średnica: 1000 mm

- Minimalna Średnica: 300 mm

- Materiał: PE

- Podwójna Ścianka: Yes

Inne specyfikacje:

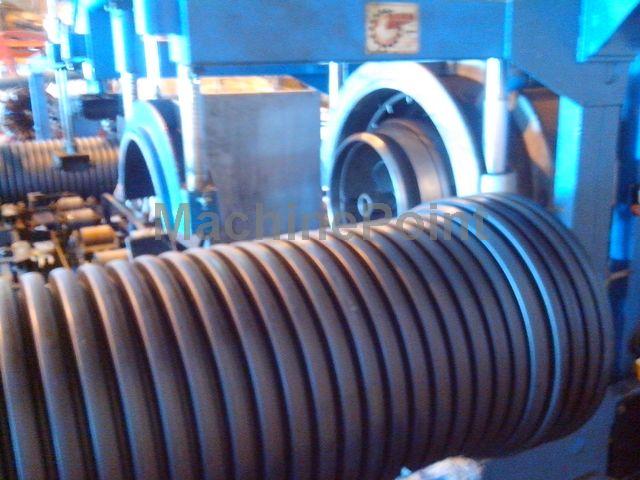

Kompletna używana linia do wytłaczania tektury Tip: UNICOR UC 1000/9 iV Rok budowy: 2000, do karbowanych rur PP / PE o podwójnej ściance do max. 1000 mm OD,

230/400 V, 50 Hz.

Linia produkcyjna jest w stanie produkować rury faliste DN/ID 300, 400, 500 i 600 mm oraz DN/OD 315 i 400 mm, zarówno PP jak i PE, i składa się z:

Item 010 10 urządzeń podających materiał, Mann + Hummel (po 4 + 1 urządzenia podające)

Item 020 2 dozowników grawimetrycznych, Maguire dla wytłaczarki warstwy wewnętrznej - zewnętrznej

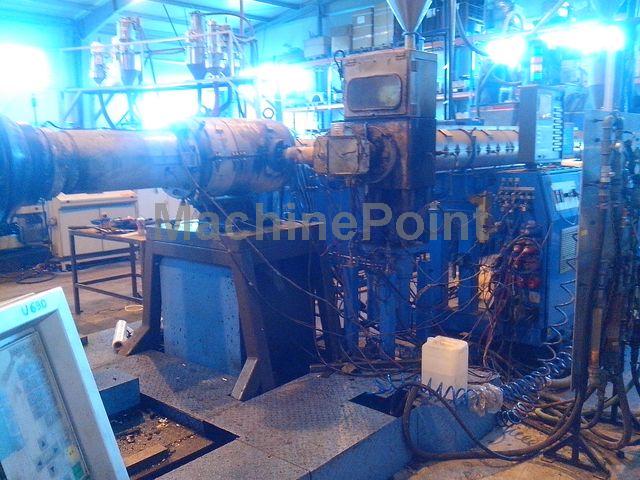

Item 030 1 wytłaczarki-kombinacji, Battenfeld 90-30 G i 120-30 G, kompletnej z pomiarem ciśnienia i temperatury stopu, wyłącznikiem czasowym, synchronizowanej z tekturnicą i urządzeniami niższego rzędu; z kompensacją wysunięcia cylindra, z rowkowaną tuleją podającą; wydajność razem ok. 1200 kg/h.

Item 040 1 zmieniacz sit do recyklingu warstwy zewnętrznej materiału, typ Kreyenborg

Item 050 1 głowica do 300 i 400 ID oraz 315 i 400 OD, UC 1000 kompletna ze wszystkimi elementami łączącymi.

Item 060 1 głowica dla 500 i 600 ID, kompletna ze stojakiem kombi dla głowicy, kompletna z wszystkimi elementami grzewczymi.

Item 070 1 zestaw matryc, kompletny z ustnikiem i końcówkami dla rozmiaru 300 mm ID, (trzpień chłodzący może być użyty alternatywnie dla SN 4, SN 8 i SN12)

Item 080 1 zestaw ustnika i końcówki z trzpieniem chłodzącym dla rozmiaru 400 mm ID. trzpień chłodzący dla rozmiaru 400 mm ID

Item 090 1 zestaw ust - i końcówka dla rozmiaru 315 OD

Item 100 1 zestaw ust - i końcówka dla rozmiaru 400 OD (Pozycje 090 i 100, są nowe, z nowym profilem, i są wyposażone w odpowiedni zestaw narzędzi do głowicy wytłaczającej i tulei)

Item 110 1 zestaw matrycy, kompletny z ustnikiem i końcówkami dla rozmiaru 500 mm ID, (trzpień chłodzący może być użyty alternatywnie dla SN 4 lub SN 8)

Item 120 1 zestaw ustnika i końcówki z trzpieniem chłodzącym dla rozmiaru 600 mm ID, (trzpień chłodzący może być użyty alternatywnie dla SN 4 lub SN 8) trzpieniem chłodzącym dla rozmiaru 600 mm ID

(Wszystkie trzpienie chłodzące są specjalnym wyposażeniem z podciśnieniem i większą ilością sekcji chłodzących w kształcie koła!)

Item 130 1 tekturnica UNICOR UC 1000/9 iV, składająca się z:

- ramy bazowej -wózka

- wyposażenia elektrycznego

- pneumatycznej jednostki procesowej do oddzielania górnego wózka matrycy

podczas utage - nośnika bloków form

- jednostki próżniowej

%Item 140 6 zestawów bloków form UC 1000, każdy z pojedynczym profilem

- kompletny dla rozmiaru 300 mm ID

- kompletny dla rozmiaru 400 mm ID

- kompletny dla rozmiaru 500 mm ID

- kompletny dla rozmiaru 600 mm ID

- kompletny dla rozmiaru 315 mm OD, (nowy, z nowym profilem)

- kompletny dla rozmiaru 400 mm OD, (nowy, z nowym profilem)

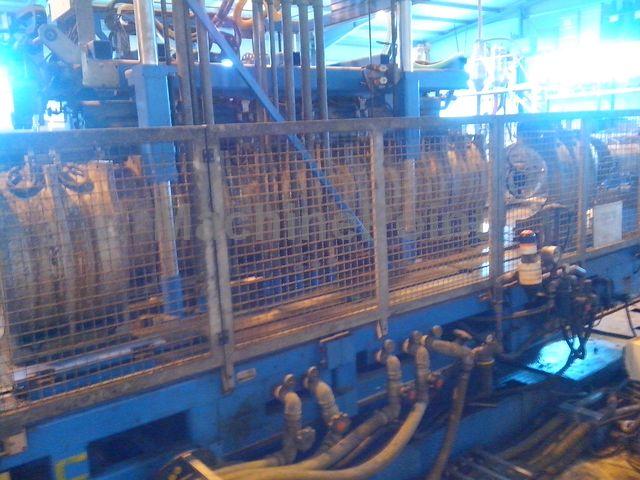

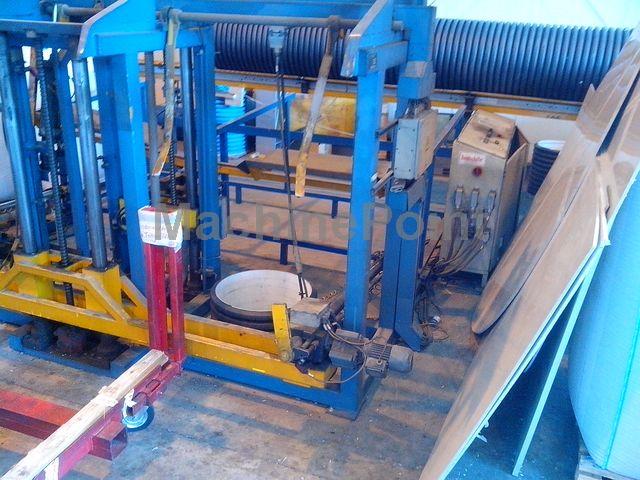

Item 150 1 chłodząca wanna natryskowa UCSB 1000, długość 4.5 m z suszarką do rur

Item 160 4 zestawy przeróbek do chłodzącej kąpieli natryskowej

Item 170 1 piła planetarna UQS 1000 do cięcia rur

Item 180 Automatyczna przepona do piły planetarnej UQS 1000

Item 190 1 stół wywrotny z przyrządem do klęczenia,

Item 200 1 maszyna do gięcia, Sica, model BACA1T-180-710, rok 1980.

Item 210 1 elewator-rotator do paletyzacji, Thyssen Nothelfer Tip RS500, w zestawie przenośnik z maszyny do belowania, rok 1990.

Pozostałe dane:

Gwarancja: Bez gwarancji

Kondycja: Maszyna obecnie pracuje

Dostępność: Od daty

Napięcie: 400 V Triphase

Częstotliwość: 50 Hz