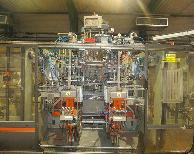

MAGIC - MGL 1D

Extrusion Blow Moulding machines up to 2 L . includes: exit conveyor, low conveyor and grinder...

2001 | 300048794 | MAGIC

Extrusion Blow Moulding machines up to 2 L . includes: exit conveyor, low conveyor and grinder...

2001 | 300048794 | MAGIC

Extrusion Blow Moulding machines up to 2 L . includes: exit conveyor, low conveyor and grinder...

1999 | 300048793 | MAGIC

Extrusion Blow Moulding machines up to 2 L . Deflashing unit NO leak tester...

1999 | 300047455 | PLASTIBLOW

Extrusion Blow Moulding machines up to 2 L . Good maintenance. Improvements made in recent years: - Change of monitor. - Replacement of battery to PLC. - System of extraction and orderly delivery of containers by extraction gripper and conveyor belt. - Leak tester integrated inside the machine...

1991 | 300044334 | UNILOY

Extrusion Blow Moulding machines up to 2 L . Mould platen sizes (mm) 140 x 100 Opening stroke 70 mm Clamping force 10 kN No deflasing unit Wall Thickness control to be overhauled...

1999 | 300044616 | MAGIC

Extrusion Blow Moulding machines up to 2 L . Continuous Blow Molding machine KAI-MEI PBS 705Q Screw diameter: 75mm Screw L/D ratio: 24/1 Screw speed:15-65 r.p.m. Mold center distance: 120 mm Dry cycle: 5,2 sec Clamping force: 13 tons Parison thickness control: MOOG DigiPack 100 points Deflashin...

2012 | 300046619 | KAI MEI

Extrusion Blow Moulding machines up to 2 L . 2 x AUTOMA PLUS AT 07D for sale (price per unit) Years: 1993 and 1995 Status: 1993 still in production, trial possible 1995 dismantled, trial not possible Materials: PE/PP blown container size: - 1 x 1L - 2 x 0,33 L - 3 x 0,25 L nu...

1995 | 300046646 | AUTOMA

Extrusion Blow Moulding machines up to 2 L . Updated GEFRAN in 12/2021 ...

1997 | 300047926 | MAGIC

Extrusion Blow Moulding machines up to 2 L . Clamping force 2 t Column distance horizontal: 240 mm Column distance vertical: 300 mm Min mold thickness 2x 102,5 mm Daylight 135 mm...

2017 | 300048798 | GENERAL PLASTICS

Extrusion Blow Moulding machines up to 2 L . Clamping force 4 t Column distance horizontal: 300 mm Column distance vertical: 400 mm Min mold thickness 2x 102,5 mm Daylight 200 mm...

2016 | 300048799 | GENERAL PLASTICS

Extrusion Blow Moulding machines up to 2 L . Extrusion Blow molder Battenfeld-Fischer VK 1-1.02 Year 1990 Motor power : 28 kW Heating power: 14 kW Two-head Center distance 100 mm Hot knife Deflashing unit Extraction gripper MOOG parison thickness control 25 points Siemens PLC Simatic S5 New ...

1990 | 300045056 | BATTENFELD FISCHER

Extrusion Blow Moulding machines up to 2 L . Automatic deflashing Leak tester...

1997 | 300047343 | AUTOMA

Extrusion Blow Moulding machines up to 2 L . Angle neck...

1997 | 300040141 | TECNOPLAST

Extrusion Blow Moulding machines up to 2 L . Extrusion Blow molder Battenfeld-Fischer VK 1-1.01 Year 1990 Motor power : 37 kW Heating power: 28 kW Two-head Center distance 100 mm Hot knife Deflashing unit Wall thickness control Profilok 32 points with 10 program memory ...

1990 | 300042450 | BATTENFELD FISCHER

Extrusion Blow Moulding machines up to 2 L . Machine components: Mitsubishi control RKC temperature controls Allen Bradley relays and contactors GE FUJI Inverters Vickers pumps and valves FESTO Pneumatic Controls SMC Pneumatic Cylinders Hot cutting blade exit conveyors flashes conveyor Externa...

2007 | 300042671 | AKEI

Extrusion Blow Moulding machines up to 2 L . Machine components: Mitsubishi control RKC temperature controls Allen Bradley relays and contactors GE FUJI Inverters Vickers pumps and valves FESTO Pneumatic Controls SMC Pneumatic Cylinders Hot cutting blade exit conveyors flashes conveyor Externa...

2009 | 300042674 | AKEI

Extrusion Blow Moulding machines up to 2 L . Extrusion Blow molder Battenfeld-Fischer VK 1-1 Year 1989 Two-head Center distance 100 mm Hot knife Deflashing unit MOOG parison thickness control 25 points...

1989 | 300042451 | BATTENFELD FISCHER

Extrusion Blow Moulding machines up to 2 L . Clamping force 15 KN Automatic deflashing unit Leak tester NO Average consumption 8 kW NEW Siemens logic PLC and touch control panel...

1994 | 300044691 | PLASTIBLOW

Extrusion Blow Moulding machines up to 2 L . PLC was replaced for a Siemens S7 In December 2019 and January 2020, the entire control system was migrated, replacing the PLC and touch screen; all the temperature controllers (originally controlled by PLC). The PLC program and the display are unpr...

2002 | 300045043 | SMC

Extrusion Blow Moulding machines up to 2 L . Mould platen sizes: 375 x 250 mm Opening stroke: 340 mm Clamping force: 50 kN Wall thickness control: 20 points Deflashing unit...

1985 | 300044981 | OMEA

Extrusion Blow Moulding machines up to 2 L . ...

1993 | 300046617 | LUXBER

Extrusion Blow Moulding machines up to 2 L . Double station Plastiblow PB2E-DL Platen size : 290 x 250 x 25 mm Opening stroke: 150 mm Clamping force 50 kN MOOG wall thickness control system Deflashing Leak tester New motor drive...

2006 | 300046367 | PLASTIBLOW

Extrusion Blow Moulding machines up to 2 L . Extrusion blow molding machine Magic MG 100D Clamping force 10 kN Max mold dimensions: 145 x 2x45 x140 mm Dry cycle 0,8 s Automatic deflashing Average consumption 12 kW...

2016 | 300044266 | MAGIC

Extrusion Blow Moulding machines up to 2 L . Single station Plastiblow PB2E-S Platen size : 350 x 200 x 35 mm Opening stroke: 150 mm Clamping force 50 kN MOOG wall thickness control system Deflashing Leak tester ...

2006 | 300046364 | PLASTIBLOW

Extrusion Blow Moulding machines up to 2 L . ...

2009 | 300047263 | UNIBLOW

Extrusion Blow Moulding machines up to 2 L . Deflashing unit - yes; leak tester - no; Mold platen size 440mm/400mm; Clamping force 130Kn Material used: HDPE : white Tipelin 6000B raw material No ancillary equipment included...

2010 | 300048262 | KAI MEI

Extrusion Blow Moulding machines up to 2 L . Automatic deflashing...

1997 | 300046016 | MECCANOPLASTICA

Extrusion Blow Moulding machines up to 2 L . Extrusion blow moulding machine year 2021 TONGDA HTSII-2L/3 double station, triple head Platen dimensions (mm) 300x320 Opening Stroke (mm) 138-368 Clamping force (kN) 40 Includes 3 sets of double moulds 100 - 200 - 250 ml + Loader + Mixer + Chiller...

2021 | 300046303 | TONGDA

Extrusion Blow Moulding machines up to 2 L . ...

1991 | 300046589 | EISA

Extrusion Blow Moulding machines up to 2 L . ...

1990 | 300044389 | ROCHELEAU

Extrusion Blow Moulding machines up to 2 L . ...

1981 | 300045183 | AUTOMA

Do you need advice?

We will guide you through the entire process of buying and selling used machinery in a changing and complex international environment. Our sales, logistics, legal, and marketing teams will accompany you throughout the process to make the operation easy and risk-free.