Head Office: Spain: Tel: +34 983 549 900

Offices In Europe: Spain: +34 983 54 99 00 | France: +33 975 181 356

Poland Plastics: +48 223 071 201

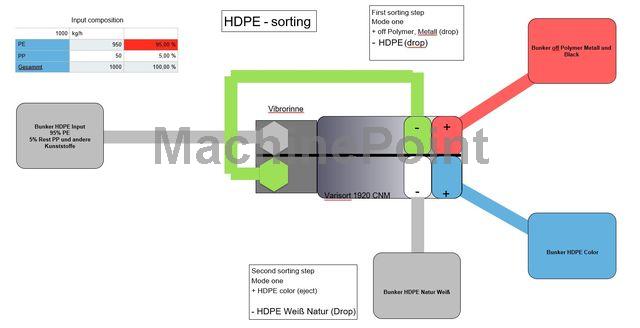

Used machine: Sorting and separating plant SESOTEC Varisort CMN 1920 - 2018

Data Sheet of Used SESOTEC Varisort CMN 1920

Ref. 300045557

Year: 2018

Brand: SESOTEC

Model: Varisort CMN 1920

Status: For sale

Technical Specifications

Other Specifications:

Input Composition

PE 950kg/h 95,00 %

PP 50kg/h 5,00 %

Total 1000 kg/h 100,00 %

Number of valves 240

Valve pitch [mm] 8

Die diameter [mm] 2.5

SENSOR UNITS

Colour C

Description: CCD line scan camera for detection of different colored material types

Color detection 2 CCD color line scan cameras

Resolution up to [mm] 0.7

Metal (M)

Description: Metal detection coil for detection of both ferrous and non-ferrous material types

Metal detection Inductive multi-channel metal detection coil

NIR (N)

Description Multispectral camera for detection of different polymers

Linear resolution 16 (detectable grain size FE: 1 / NE: 1.5)

Multispectral detection Multispectral camera, 1330 - 1900 nm

Detection up to [mm] 8

Suitable particle sizes [mm] 15 - 300

Throughput up to [t/h]* 6

Operating voltage [VAC] 400

Rated current [A] 9-16

Power [KVA] 6.3 - 11

Electrical connection Power supply cable 5 x 4 mm²; 3 x 1.5 mm²

Electrical fuse 25 A (slow blow fuse)

Protection class IP 54

Temperature range +5° C - +40° C

Painting RAL 9007

Sound pressure amplitude idle < 80dBa, full load <= 90dBa

Compressed air connection [in] 1 1/2

Required air pressure [bar] 6-8

Compressed air consumption [m³/min]** 1-5

Unit Division

Separation of the sorting device for parallel sorting of two different material streams or for 2-stage sorting

Conveyor length

Conveyor belt with a speed of up to 4 m/s for optimal distribution and separation of the elements in the material stream to increase the throughput

3rd chute

Additional 3rd chute and 2nd valve bar for sorting the input material stream into 3 fractions

Valve grid

Alternative valve grid possible for certain sorting applications

Sensor upgrade

Pre-wiring for possible sensor upgrade

Stainless steel detection unit

Multi-channel stainless steel detection coil for detection of stainless steel 30 mm x 30 mm and larger

VISUTEC data management software

Networking of the sorter with a PC on which VISUTEC is installed (remote maintenance, software updates)

Vibratory feeder material flow

Vibratory feeder complementing the sorter for optimum distribution and separation of the elements.

Roller apex

Roller apex on the separator to avoid material accumulation

Foil chute between conveyor belt and separator housing for separation of light material

Belt cleaner

Rotating brush under the conveyor belt for cleaning the belt

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown with material