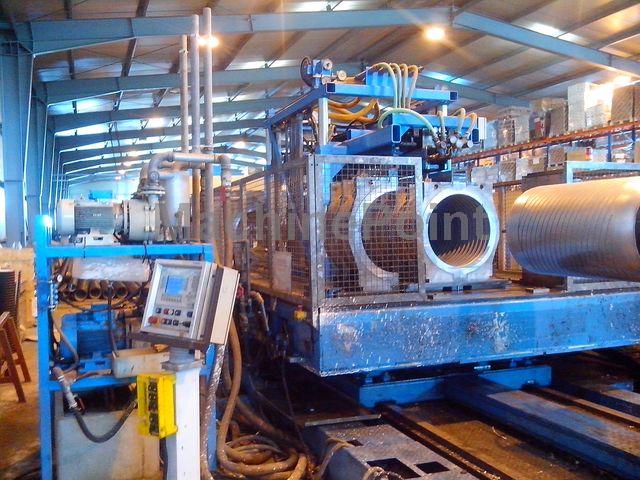

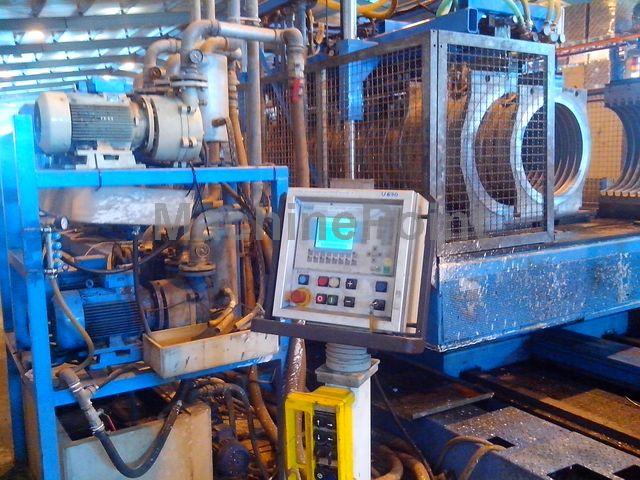

Used UNICOR UC 1000/9 iV of 2000 for sale

Extrusion line for corrugated pipes UNICOR, MachinePoint offers their clients all the services necessary to buy the machine: Transport, dismantling, and legal consultancy.

Data Sheet of Used UNICOR UC 1000/9 iV

Ref.: 300033840

Year: 2000

Brand: UNICOR

Delivery time: From date

Ask for machine price Want to sell your machine?

Technical Specifications:

- Maximum Diameter: 1000 mm

- Minimum Diameter: 300 mm

- Material: PE

- Double Wall: Yes

Other Specifications:

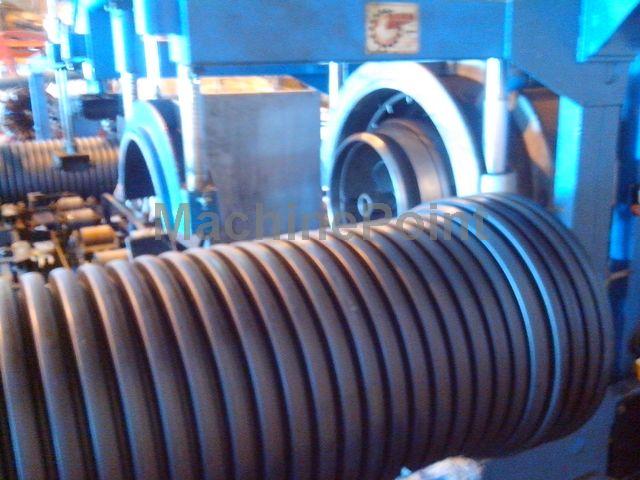

Complete used Corrugator extrusion line Tip: UNICOR UC 1000/9 iV Year of building: 2000, for corrugated PP / PE double wall pipes up to max. 1000 mm OD,

230/400 V, 50 Hz.

The production line is capable of producing corrugated pipes DN/ID 300, 400, 500 and 600 mm and DN/OD 315 and 400 mm, both PP and PE, and consisting of:

Item 010 10 material feeding devices, Mann + Hummel (each 4 + 1 feeder devices)

Item 020 2 Gravimetric dosing devices, Maguire for inner- outer layer extruder

Item 030 1 Extrudercombination, Battenfeld 90-30 G and 120-30 G, complete with melt pressure- and melt temperature measurement, time switch, synchronistic with corrugator and downstream equipment; with compensation of the extension of the cylinder, with grooved feed bush; output together ca. 1200 kg/ h.

Item 040 1 screen changer for recycling material outer layer, Type Kreyenborg

Item 050 1 die head for 300 and 400 ID and 315 and 400 OD, UC 1000 complete with all connections pieces.

Item 060 1 die head for 500 and 600 ID, complete with combi support stand for die head, complete with all heating elements.

Item 070 1 die set, complete with mouth - and end pieces for size 300 mm ID, (cooling mandrel can be used alternatively for SN 4, SN 8 and SN12)

Item 080 1 set mouth - and end piece incl. cooling mandrel for size 400 mm ID

Item 090 1 set mouth – and end piece for size 315 OD

Item 100 1 set mouth – and end piece for size 400 OD (Items 090 and 100, are new, with the new profile, and are accompanied by appropriate tool kit for extrusion die head and sleeves)

Item 110 1 die set, complete with mouth - and end pieces for size 500 mm ID, (cooling mandrel can used alternatively for SN 4 or SN 8)

Item 120 1 set mouth- and end piece incl. cooling mandrel for size 600 mm ID

(All cooling mandrels are special equipment with vacuum and more circle-cooling sections!)

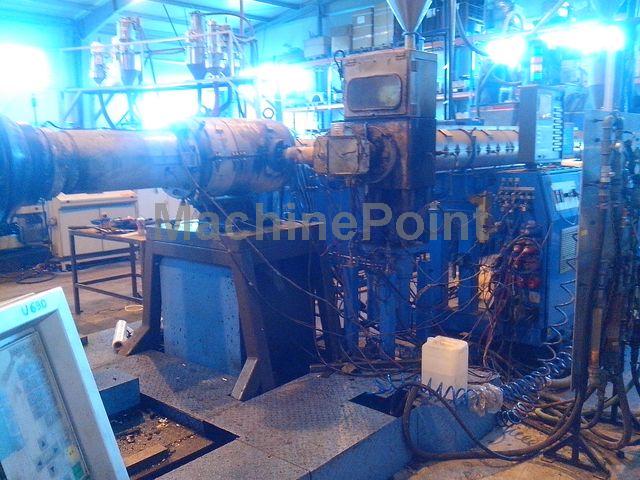

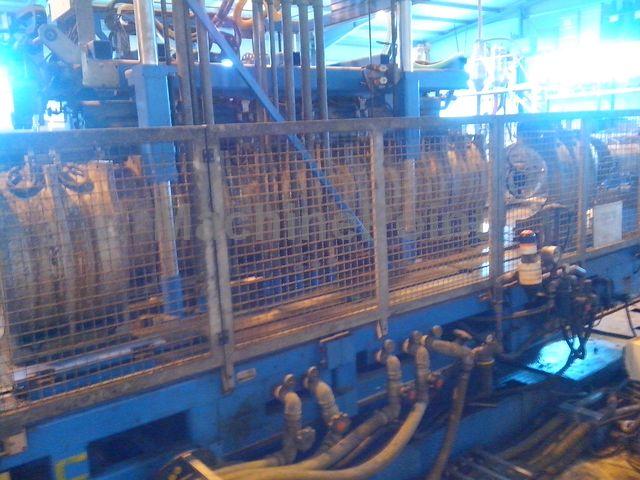

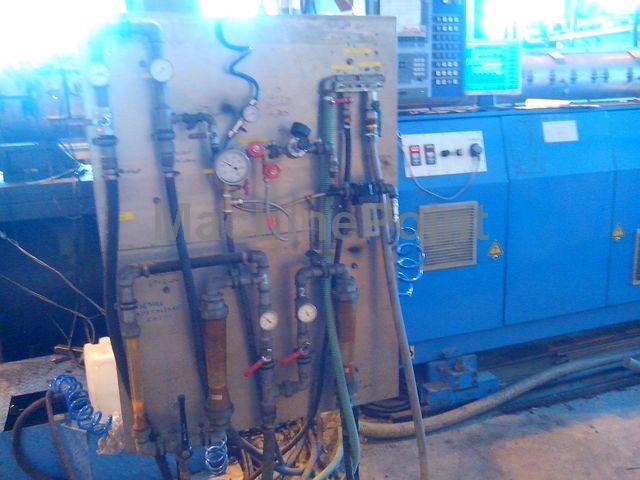

Item 130 1 corrugator UNICOR UC 1000/9 iV, consisting of:

- base frame -carriage

- electrical equipment

- pneumatic process unit for separation of the top carriage of the die

during utage - mould block carrier

- vacuum unit

Item 140 6 mould block sets UC 1000, each with single profile

- complete for size 300 mm ID

- complete for size 400 mm ID

- complete for size 500 mm ID

- complete for size 600 mm ID

- complete for size 315 mm OD, (new, with the new profile)

- complete for size 400 mm OD, (new, with the new profile)

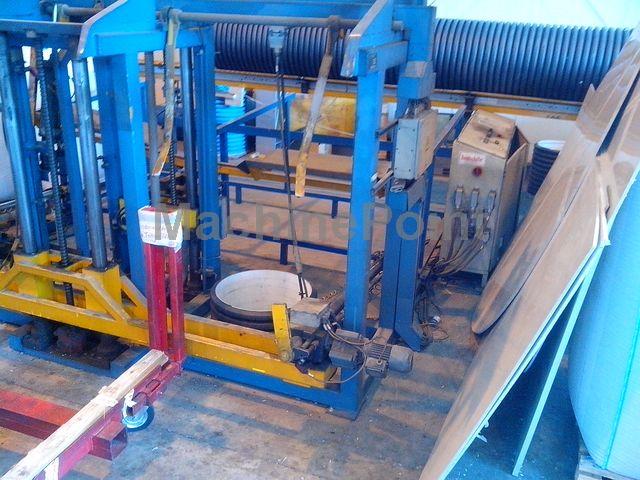

Item 150 1 cooling spray bath UCSB 1000, length 4.5 m with pipe dryer

Item 160 4 alterations sets for cooling spray bath

Item 170 1 planetary saw UQS 1000 for cut of the pipes

Item 180 Automatic diaphragm for planetary saw UQS 1000

Item 190 1 tipping table with kneeling device,

Item 200 1 belling machine, Sica, model BACA1T-180-710, year 1980.

Item 210 1 elevator-rotator for palletizing, Thyssen Nothelfer Tip RS500, the transfer

conveyor from belling machine included, year 1990.

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: From date

Voltage: 400 V Triphase

Frequency: 50 Hz