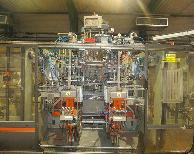

MAGIC - MG 100D

Extrusion Blow Moulding machines up to 2 L . Extrusion blow molding machine Magic MG 100D Clamping force 10 kN Max mold dimensions: 145 x 2x45 x140 mm Dry cycle 0,8 s Automatic deflashing Average consumption 12 kW...

2016 | 300044266 | MAGIC