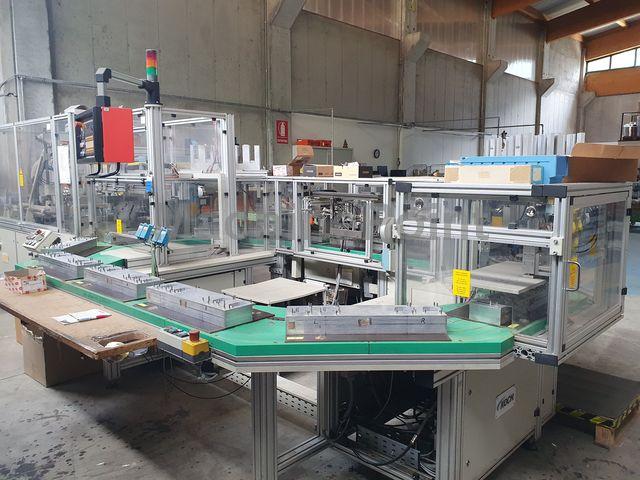

Used KOCH KBS-PT of 1997 for sale

Blister and Skin KOCH, MachinePoint chooses the best machinery on sale in the market and we offer our clients a selection of high quality machinery.

Data Sheet of Used KOCH KBS-PT

Ref.: 300044275

Year: 1997

Brand: KOCH

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Machine Type: Blister

- Material : PVC

- Forming Area (Vxh): 250x500

Other Specifications:

Automatic intermittent motion blister packaging machine with a capacity of up to 15 cycles per minute.

Fast format changeover, high packaging capacity and flexibility in processing different formats and materials. Sealing pallets can be changed very quickly.

During format changes, only individual format parts are replaced and not the complete set. This is an important advantage when packing small batches efficiently.

Forming depth: 67 mm.

Sealing format: 320 x 600 mm.

Output: 15 cycles/min depending on film, pack shape, pack size and sealing duration by forming rigid PVC film, PVC / CARDBOARD

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown with material

Availability: Immediate

Voltage: 400 V Triphase

Frequency: 50 Hz

Voltage: 15 Kw