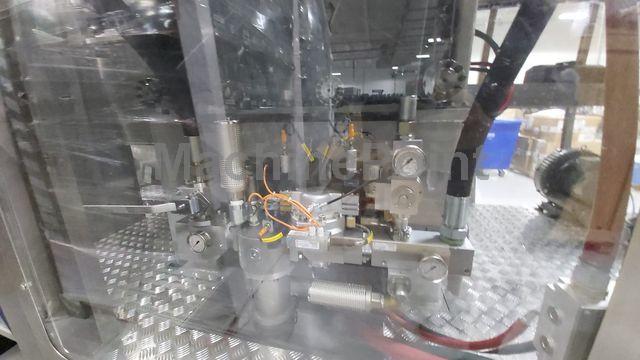

Used SERAC SBL SL7/8 of 2020 for sale

Stretch blow moulding machines SERAC, We provide a quality service in the buying and selling of used machinery, with all the services necessary to achieve a successful transaction.

Data Sheet of Used SERAC SBL SL7/8

Ref.: 300044739

Year: 2020

Brand: SERAC

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Neck: 38

- Output: 10500 U/h

- Preform Feed System: Yes

- Container Size (Max.): 1.5 l

- Number Of Cavities: 7

- Materials: PET

- Reheat: No

Other Specifications:

Serac blow molding machine- SBL SL7/8 - 2020

Neck 38

7 cavities

Output 10.500 u/h

Still installed and can be seen with material.

In excellent condition and used for trials only

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown in dry cycle

Availability: Immediate