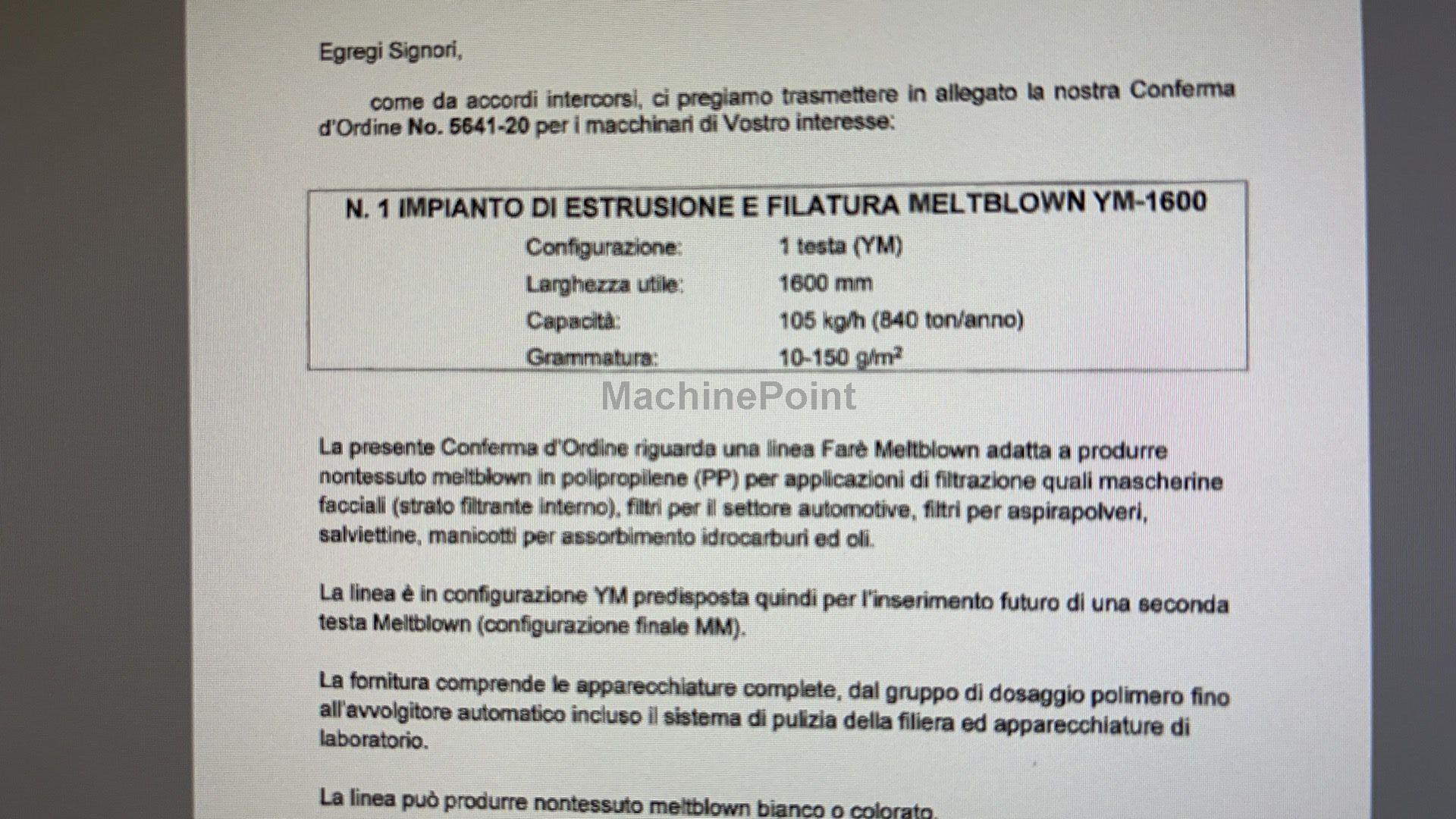

Used FARE YM-1600 of 2021 for sale

Extrusion lines for nonwovens FARE, We provide a quality service in the buying and selling of used machinery, with all the services necessary to achieve a successful transaction.

Data Sheet of Used FARE YM-1600

Ref.: 300045509

Year: 2021

Brand: FARE

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

Other Specifications:

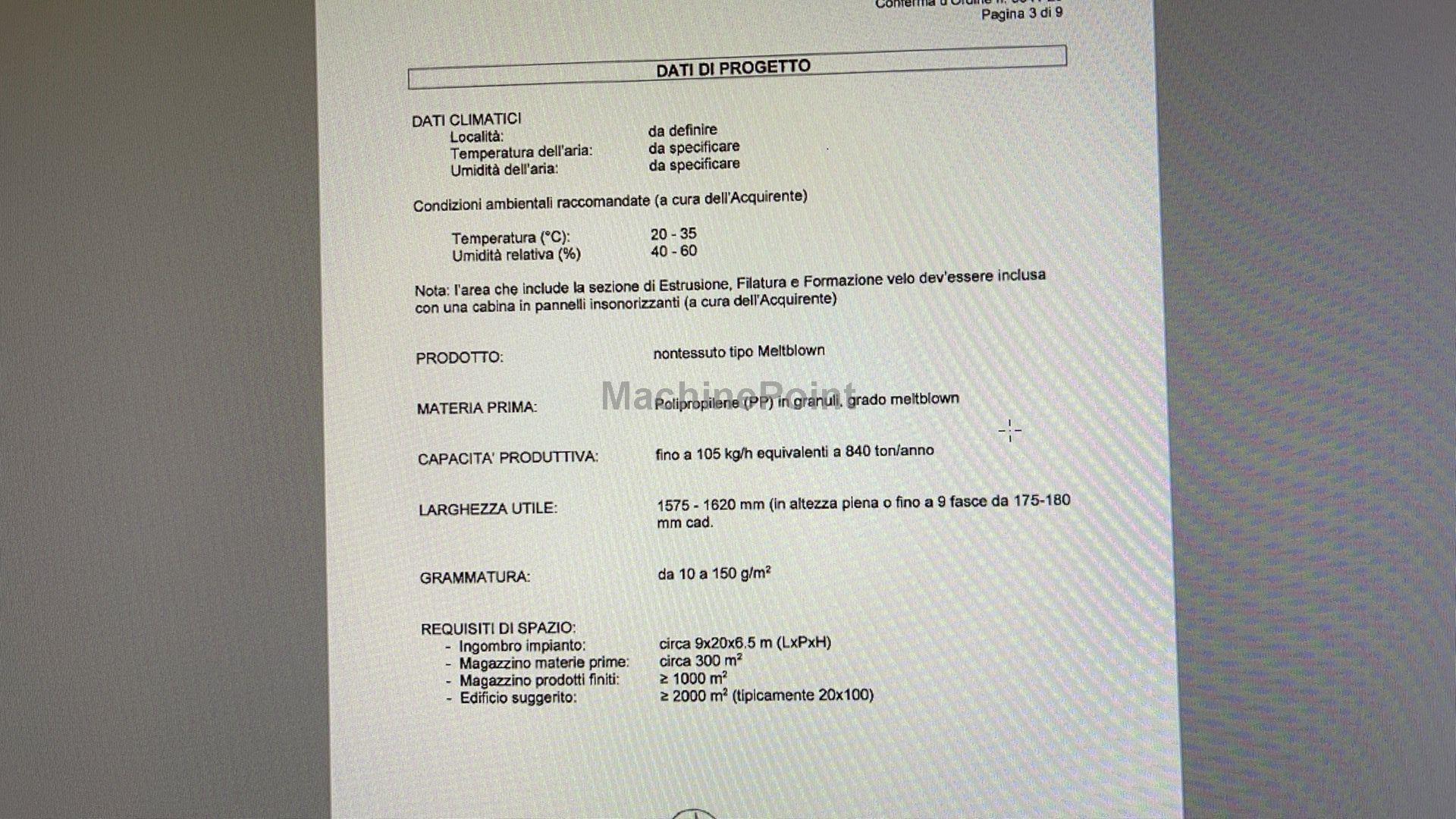

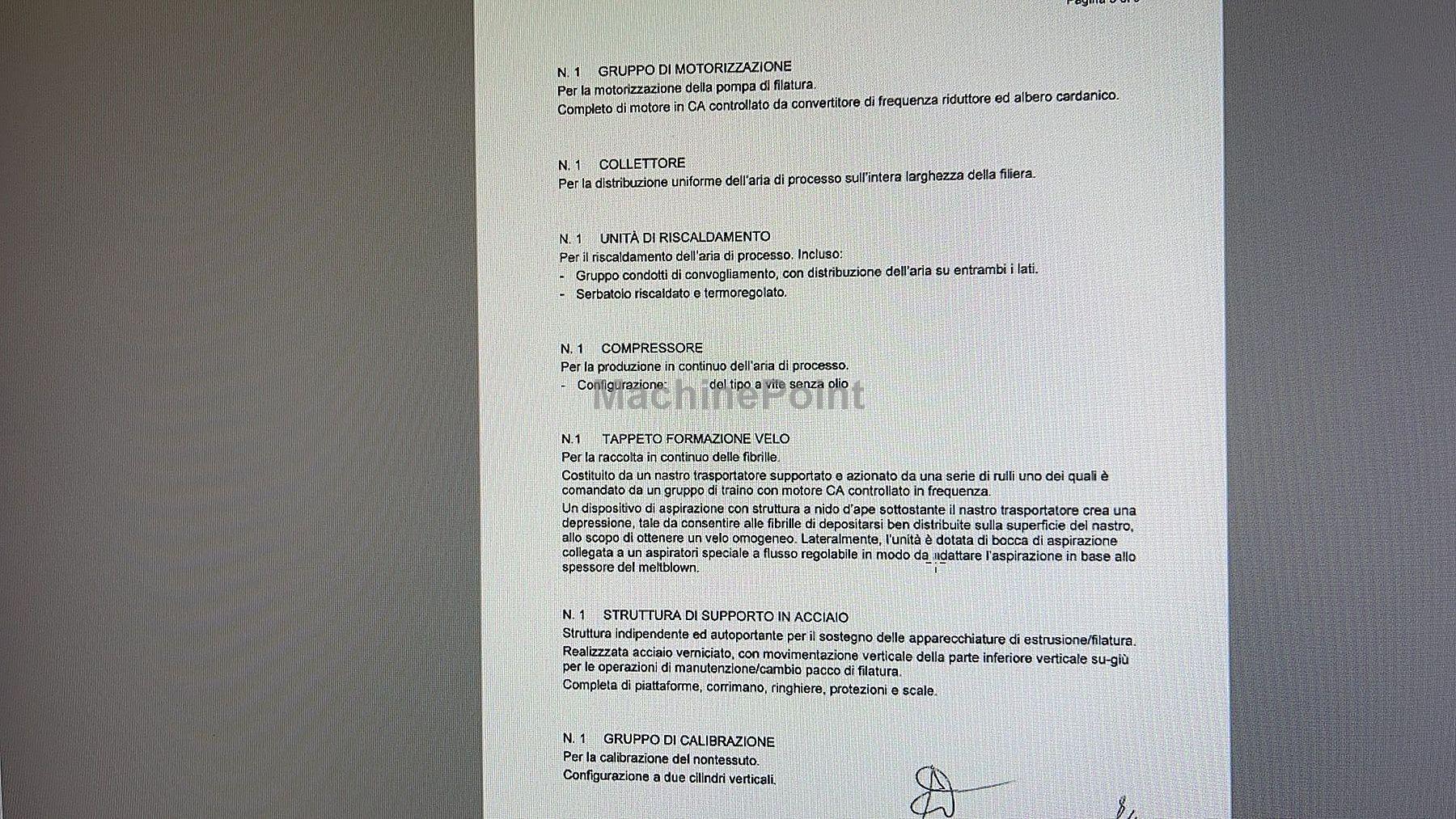

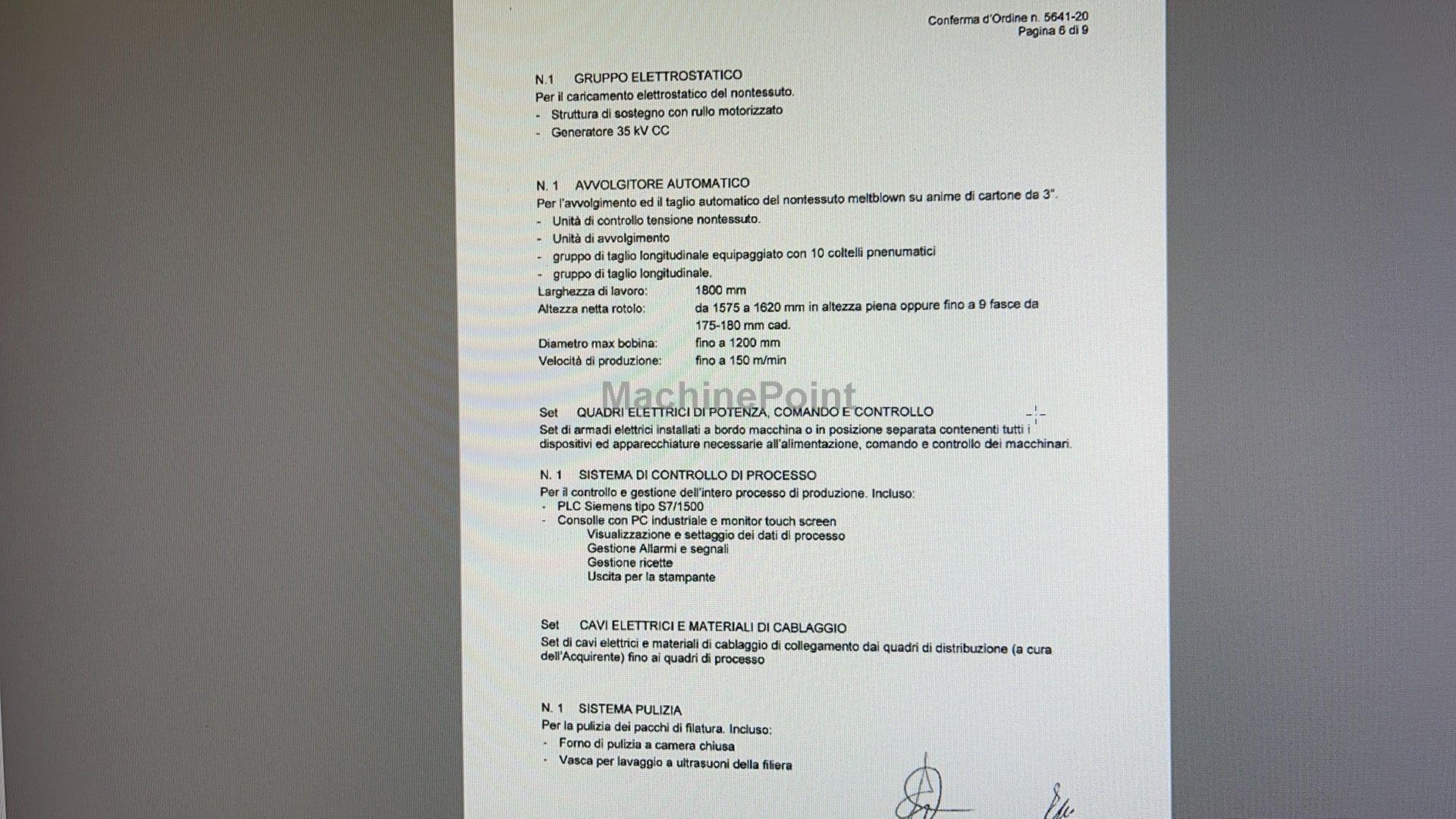

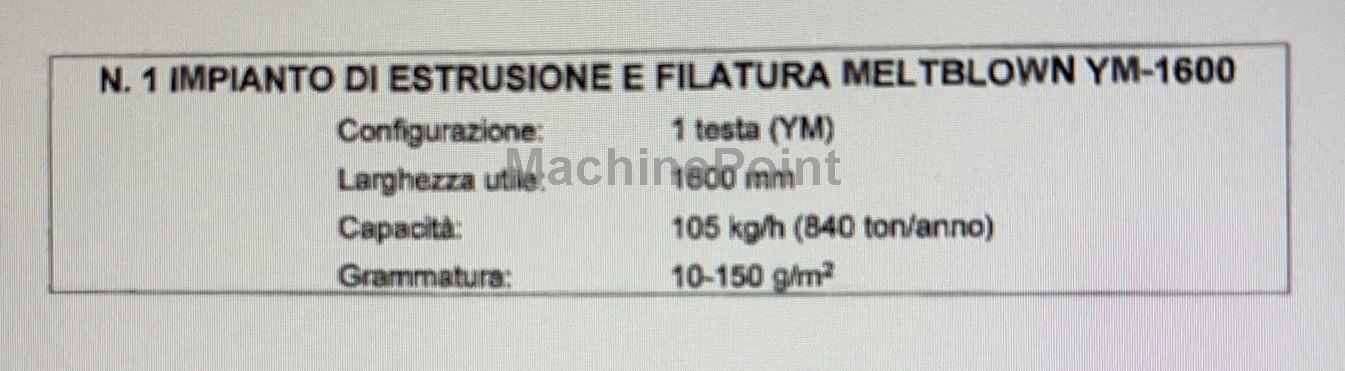

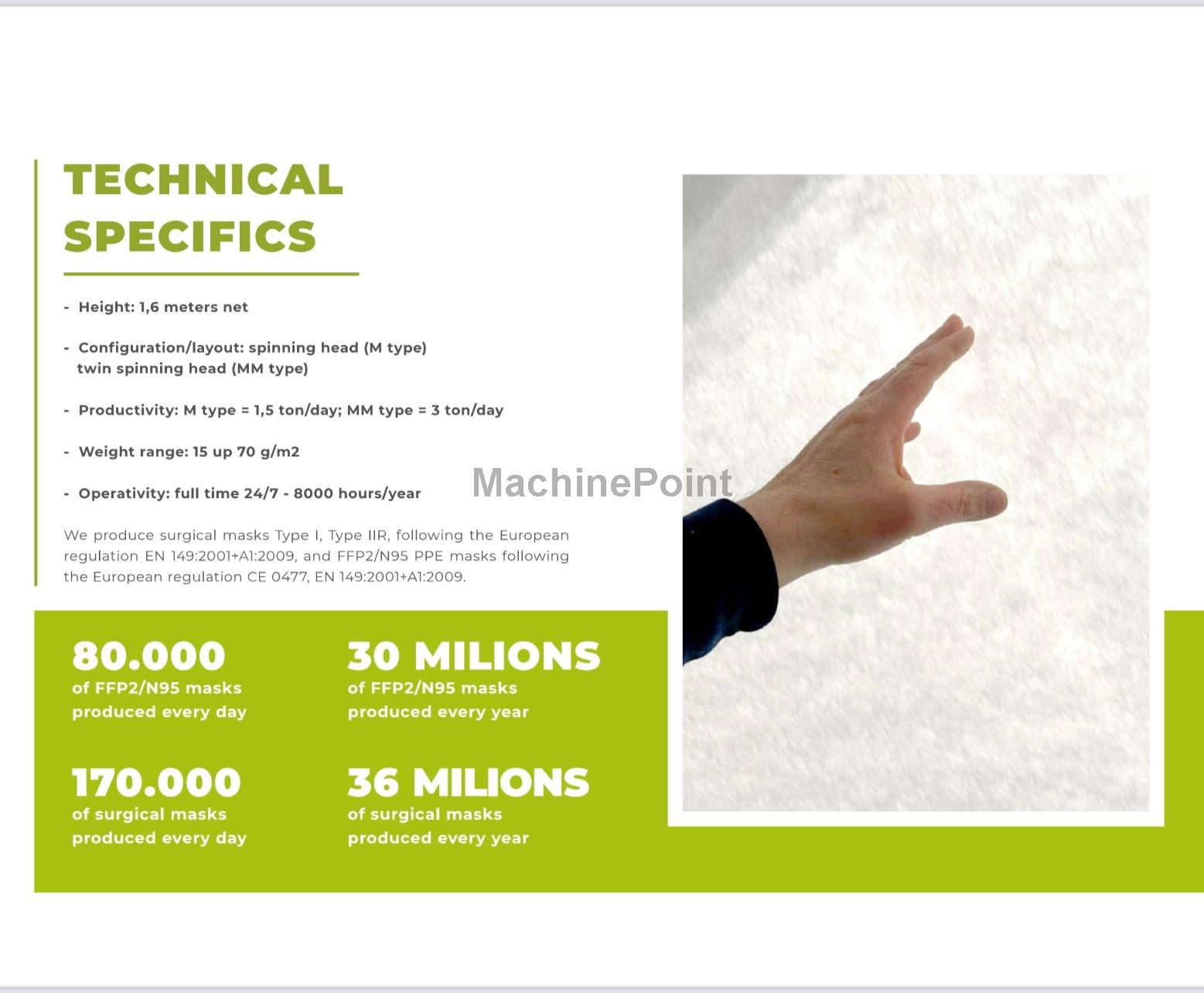

Meltblown extrusion plant suitable for producing PP meltblown nonwoven for filtration applications such as face masks, automotive filters, vacuum cleaner filters, wipes, hydrocarbon and oil absorption sleeves

1 head with provision for inserting a second head

Useful width 1575- 1600 mm

Maxi output 105 kg/h

Grammage 10-150 gr/m2

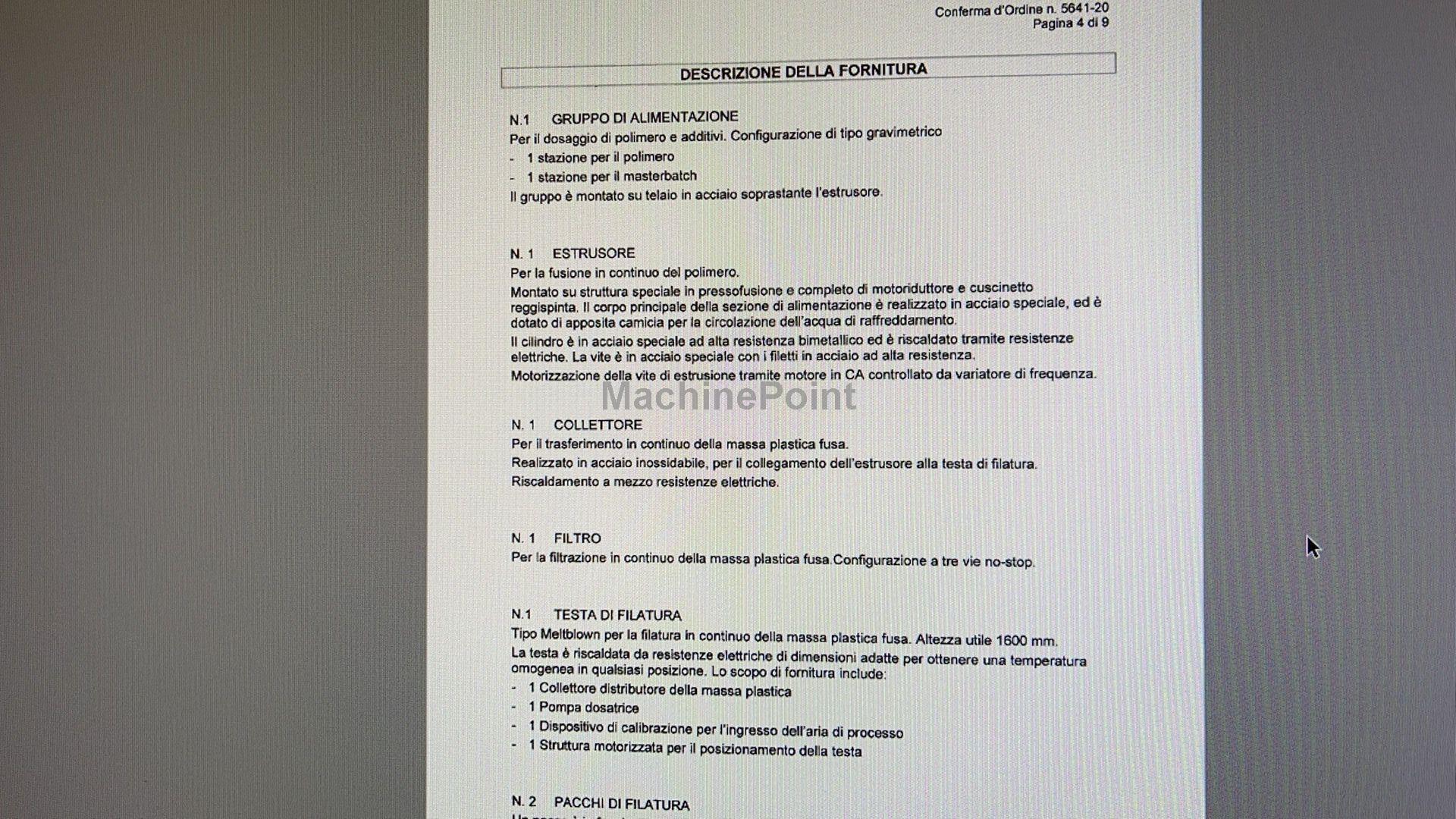

Dosing group 1 +1

Non stop filter

Meltblown head, width 1600 mm

Electrostatic group

Automatic winder with cutting unit with 10 knives . Shafts 76 mm

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown with material

Availability: Immediate