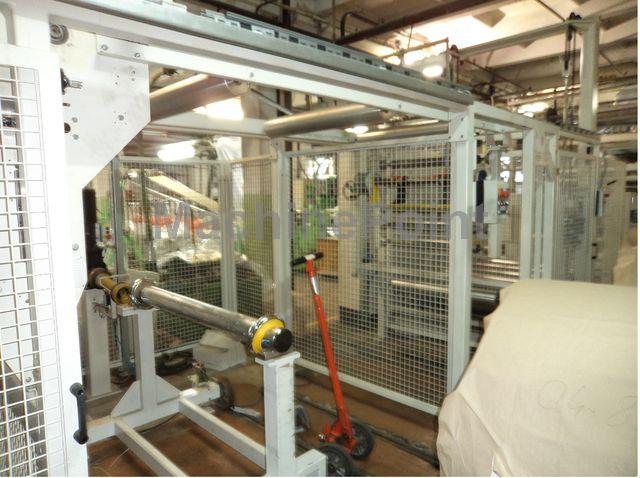

Used BATTENFELD-CINCINNATI OLV 400/1050 of 2012 for sale

Sheet monoextrusion lines BATTENFELD-CINCINNATI, MachinePoint has a multicultural team with world presence to be able to be closer to our clients. We speak over 15 different languages.

Data Sheet of Used BATTENFELD-CINCINNATI OLV 400/1050

Ref.: 300038633

Year: 2012

Brand: BATTENFELD-CINCINNATI

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Materials: PP, PS

- Film Width (Max): 850 mm

- Film Thickness (Min): 0.3 mm

- Film Thickness (Max): 2 mm

- Output Capacity: 400 kg/h

- Layers: 1

- Number Of Extruders: 1

- · EXTRUDER: BATTENFELD-CINCINNATI BEX 1-75-34V

- Screw Diameter: 75 mm

- Screw L/D Ratio: 34

- Motor Rating: 135 kW

- Heating Zones (Extruder): 8

- Heating Capacity: 50 kW

- Screen Changer: Yes

- · DIE HEAD: YES

- Number Of Rolls: 3

- Roll Width: 1000 mm

- Roll Diameter: 400 mm

- Roller Cooling: Yes

- Rewind Unit Type: Double SANDER

- Rewind Roll Diameter: 1400 mm

- Rewind Roll Width: 1000 mm

Other Specifications:

Complete extrusion line for PP and PS sheet production.

2 dosing units Moretto S.P.A., 2014.

Min. - Max. sheet width: 350 - 850 mm

Min. - Max. sheet thickness: 300 - 2000 microns

Head width: 1000 mm

Lip gap: 2 mm

Degassing system: No

Calender: OLV 400/1050

Double winder SANDER

Max. roll weight: 1 500 kg

Mandrel diameter: 76, 120, 152, 200 mm.

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown with material

Availability: Immediate

Voltage: 400 V Triphase

Frequency: 50 Hz