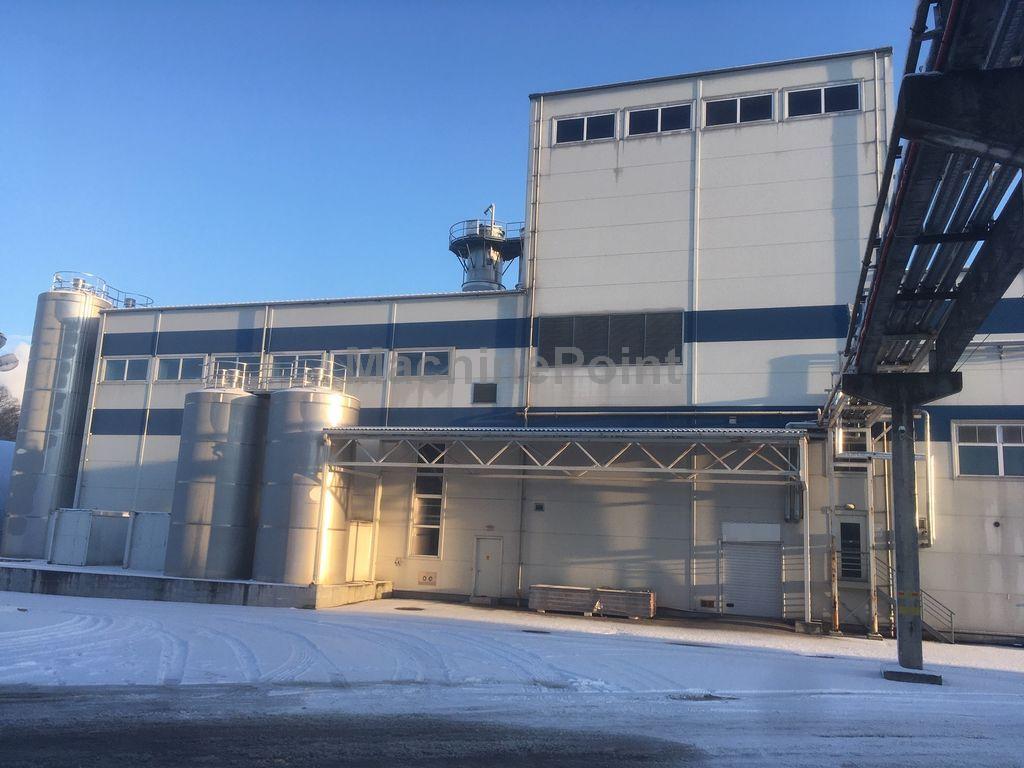

Used TETRA PAK Tetra Pak, M&L Engineering, Vzduchotorg of 2006 for sale

Other Dairy Machine Type TETRA PAK, In MachinePoint we work so that our buyers receive a professional service and so the transaction is safe.

Data Sheet of Used TETRA PAK Tetra Pak, M&L Engineering, Vzduchotorg

Ref.: 300040687

Year: 2006

Brand: TETRA PAK

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Type: Powder whey and milk plant

Other Specifications:

Complete plant for whey and milk powder

- Tanks for whey 2 x 50t

- Pasteurizer TetraPak T=74C 24000L/h, UT40 BC-16

- Tanks for pasteurized whey 2 x 100t

NO separator

- Drying process M&L Engineering : 25000 kg /h

I stage – output 4300 kg/h product, 20 700 kg/h, water content evaporated

II stage - output 2500 kg/h produc, 1800 kg/h , water content evaporated

Processing: 480 t / 24h

Production -20h, CIP 4h.

- Tanks for crystallized whey 4 x 12.5t, time for crystallization 12h

- Spray drier Vzduchotorg VRC4 - 1418kg/h product, 1082kg/h evaporation

- Cream tank 4000

- Powder tank 15000l

- Packing 25kg and 100kg bags.

The plant is still installed, but out of use.

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown in dry cycle

Availability: Immediate

Clasification:

Final Products: Milk powder