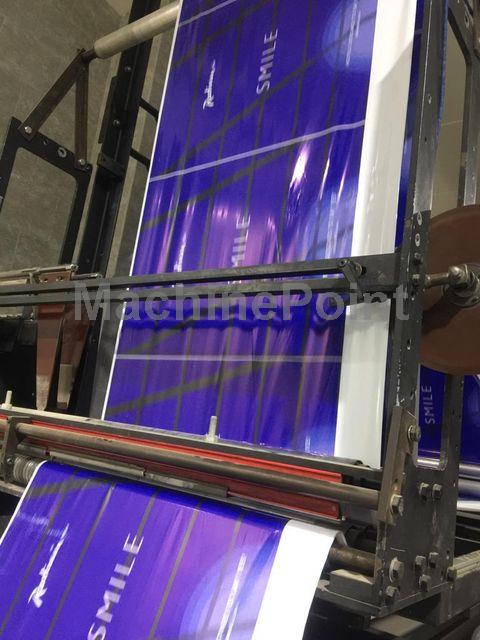

Used LEMO IS 850 DKT of 2002 for sale

Patch handle bag making machine LEMO, The team at MachinePoint will accompany you through the whole process of buying the machine.

Data Sheet of Used LEMO IS 850 DKT

Ref.: 300041588

Year: 2002

Brand: LEMO

Delivery time: Immediate

Ask for machine price Want to sell your machine?

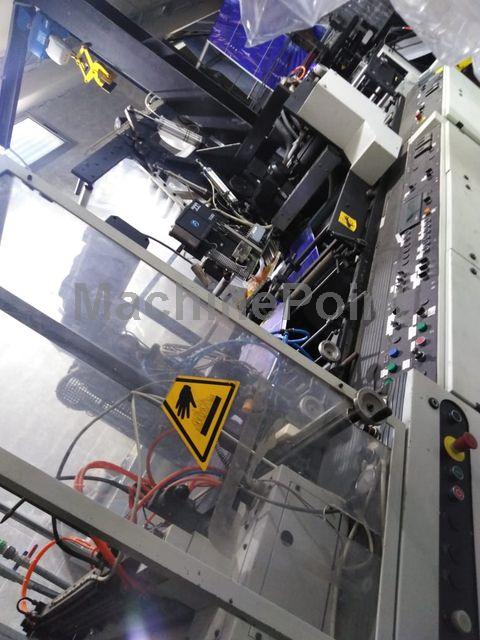

Technical Specifications:

- Welding Width: 850 mm

- Bag Length (Max): 850 mm

- Bag Length (Min): 250 mm

- Cycles Per Minute: 230 U/min

- Film Speed: 120 m/min

- Drive: Servo

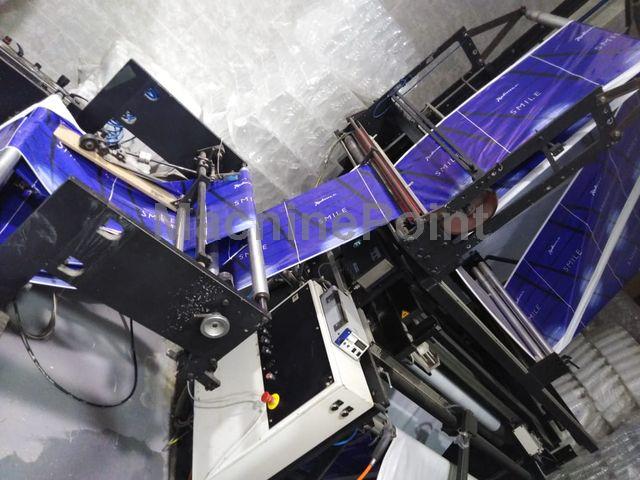

- Number Of Lanes: 1

Other Specifications:

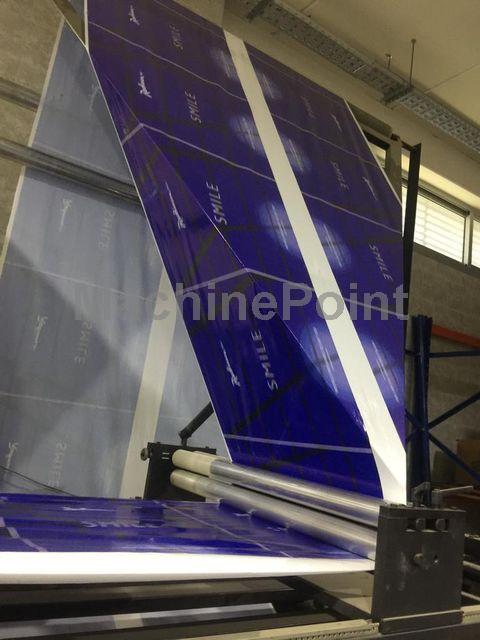

Driver unwinder 1700 mm

Gusset 0,2- 8 mm

Web guide Fife

V-fold station

Glue reinforcement

Handle punching unit

Photocell

Antistatic bar

Other Details:

Guarantee: Without guarantee

Current condition: Disconnected. Can't be seen in running condition

Availability: Immediate

Voltage: 400 V Triphase

Frequency: 50 Hz

Voltage: 40 Kw