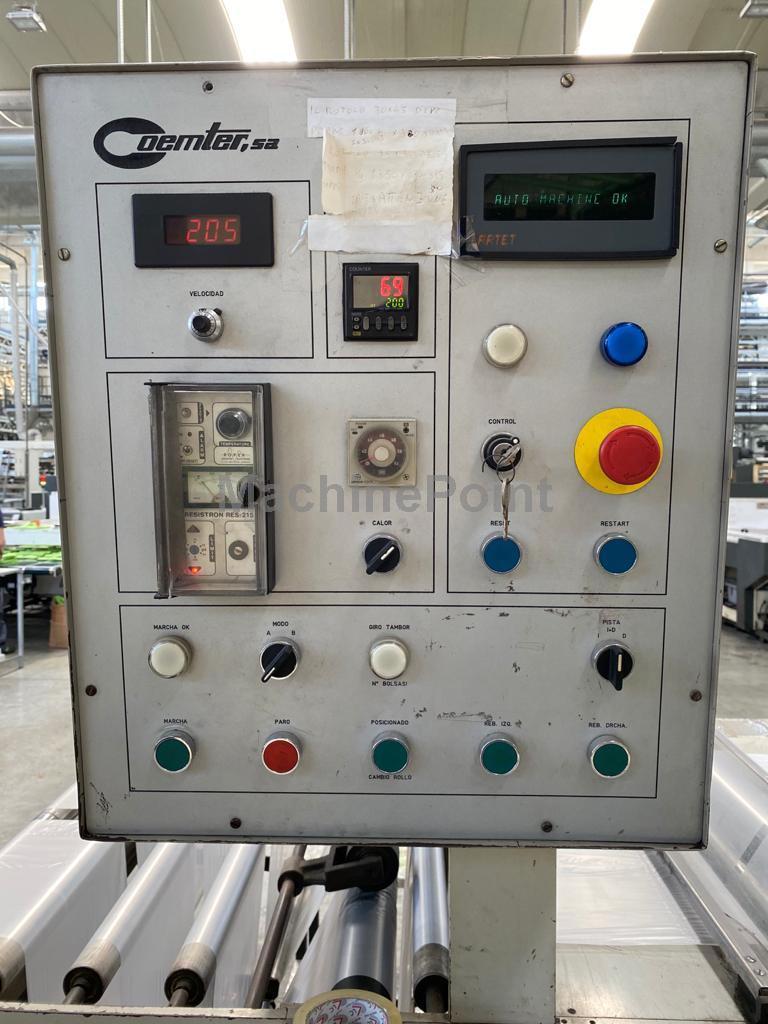

Used COEMTER Ter Core 9270 38/25 of 1996 for sale

Bottom weld bags on the roll COEMTER, We provide a quality service in the buying and selling of used machinery, with all the services necessary to achieve a successful transaction.

Data Sheet of Used COEMTER Ter Core 9270 38/25

Ref.: 300042009

Year: 1996

Brand: COEMTER

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

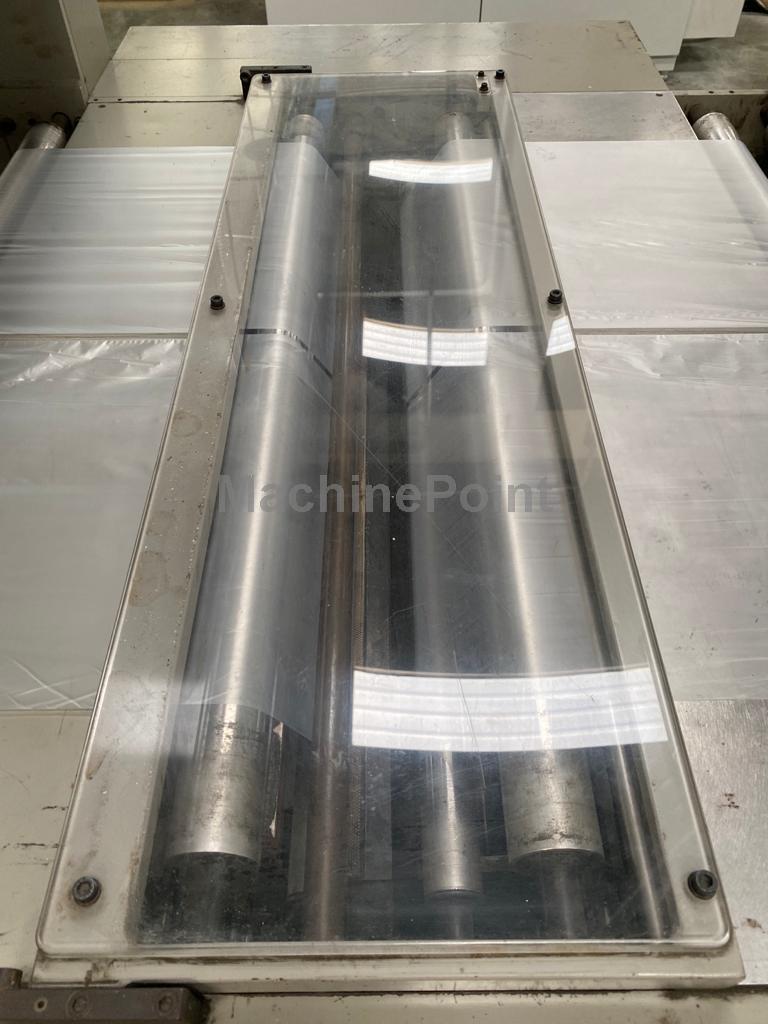

- Welding Width: 700 mm

- Bag Length (Max): 1790 mm

- Bag Length (Min): 285 mm

- Film Speed: 100 m/min

- Drive: Servo

- Number Of Lanes: 2

- Rolls Production: 20 U/min

Other Specifications:

Format length with:

4 sealing stations 285-470 mm

2 sealing stations 470 - 930 mm

1 sealing stations 930 - 1790 mm

Welding width 320x2 mm

Roll width 100 - 380 mm

Roll diameter max. 250 mm

Inner diameter of mandrel 25 - 40 mm

Bags / minute Max. 4 / 2 / 1 sealing stations :

300x2 / 150x2 75x2

Rolls / minute Max. 10x2

Other Details:

Rebuild: 2008

Guarantee: Without guarantee

Current condition: Dismantled. Can be assembled to see running with material

Availability: Immediate

Voltage: 380 V Triphase

Frequency: 50 Hz

Voltage: 10 Kw