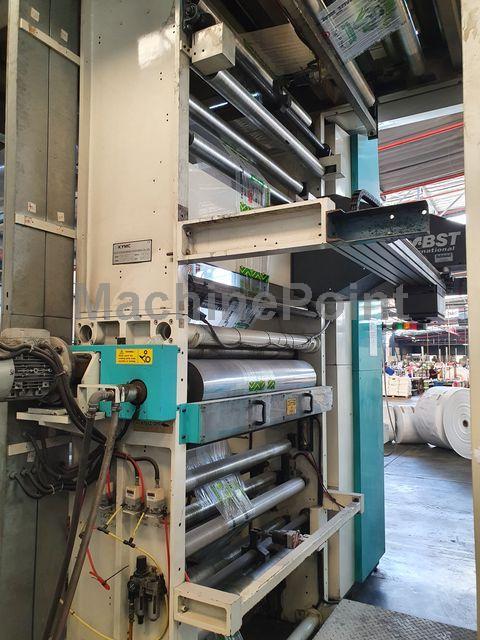

Used KYMC FX 8120 of 2010 for sale

8 Colours CI Flexo Printing Machines KYMC, You can contact our team and analyze your needs so we can offer you the best possible solution depending on your budget.

Data Sheet of Used KYMC FX 8120

Ref.: 300042724

Year: 2010

Brand: KYMC

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Printing Width: 1170 mm

- Web Width: 1200 mm

- Printing Repeat (Max): 1000 mm

- Printing Repeat (Min): 360 mm

- Plate-Cylinder Gear-Pitch Module: 5 mm

- Drying System: Electrical

- System: Geared

Other Specifications:

Materials: LDPE, LLDPE, HDPE, Polypropylene, Polystyrene, Polyester, Metallized films, Light weight paper, etc.

Min. printing width: 55% of the max. web width.

Max. machine speed: 300 m/min

Printing speed: 250m/min, the effective printing speeds will depend on several printing conditions.

Heat source: Electric elements

PRINTING SECTION

Micrometric adjustment of pressure on every axis.

Between colour drying modules made of stainless steel with dampers.

Motorized forward and backward control of printing station by push button.

Pre-register for quickly set-up of printing registration.

Water conditioning devise to maintain drum at exact temperature while running the machine or during operation stopped.

OVERHEAD STRUCTURE

All aluminium idle rollers.

Extended final drying tunnel.

2 drying blowers with heaters and dampers, one for the oven & one for the in between colour dryers.

2 exhaust blowers, one for the oven & one for the in between colour dryers.

Infeed automatic edge position control. (E&L Germany) > must be fixed, not working.

Static bar prior to print.

UNWIND SECTION

Outside diameter of reels: max. 800mm.

Indexing of arms through auxiliary AC motor and reducer with AC vector drive from YASKAWA.

Two unwinding stations, driven by two AC vector motors, controlled through dancing roller for

automatic tension regulation.

Pneumatically activated cutting group for automatic flying splice at full production speed.

Air shaft (2) with expansible rubber lather for cores having internal diameter 76mm.

REWIND SECTION

Outside diameter of reels: max. 800mm.

Indexing of arms through auxiliary AC motor and reducer.

Two rewinding stations, driven by two AC vector motors, controlled through dancing roller for the automatic tension regulation.

Reel change sequence to be activated by the operator: start of the free reel shaft; once it has reached the same speed of the machine, the operator can then activate the splice.

N°2 shafts, with expansible rubber lathes for cores having internal diameter 76mm.

PNEUMATIC dancing roller for automatic tension control on rewinder.

Static bar after print.

Sleeves :

8 x (490,520,550,580,600,620,710,740,800,850,870,910,1000)

11 x 680

9 x Carrier for 680 mm to 850 mm

9 x Carrier for 850 mm to 1000 mm

Anilox : (Line L/cm - cm3/m2)

80 - 12,0 (damaged, not in use)

100-10,0

115-9,0 (damaged, not in use)

120-8,2

120-8,4

120-10,2

140-16,2

280-3,7

315-3,0 (2x)

315-3,2

MOUNTER PROOFER MODEL: SM-1200 included:

Maximum repeat of plate cylinder: 1000mm

Minimum repeat of plate sleeve: 400mm

Maximum width of plate sleeve face: 1200mm

Electric supply: 220V/1p/50HZ

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown in dry cycle

Availability: Immediate

Voltage: 380 V Triphase

Frequency: 50 Hz