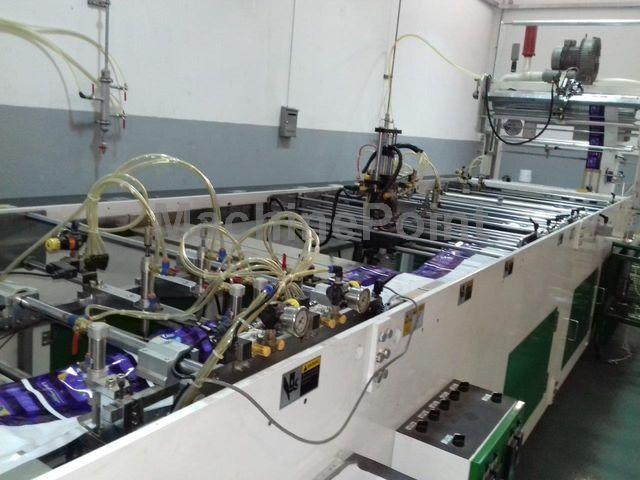

Used HEMINGSTONE HM-1250 UD+SHD+W of 2013 for sale

Bag making machine for baby diapers bags HEMINGSTONE, In MachinePoint we work so that our buyers receive a professional service and so the transaction is safe.

Data Sheet of Used HEMINGSTONE HM-1250 UD+SHD+W

Ref.: 300044587

Year: 2013

Brand: HEMINGSTONE

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Welding Width: 600 mm

- Bag Length (Max): 600 mm

- Bag Length (Min): 200 mm

- Film Thickness (Max): 0.1 mm

- Film Thickness (Min): 0.03 mm

- Gusseting: Bottom

- Film Speed: 50 m/min

- Drive: Servo

- Unwinder Type: Single

- Mother Reel Width: 1600 mm

- Mother Reel Diameter (Max): 800 mm

- Edge Guide: Yes

- Number Of Lanes: 1

- Folding Unit: V-Folder

- Sealing Bar: Side

- Bag Delivery: Stacking table

- Pre-Cutting Sealing Unit: Yes

- Handle Punching Unit: Yes

- Patch Handle: Yes

Other Specifications:

High Performance Bag making line for the production of Paramount bags, cross handle bags, and wicket bags

For Paramount & Cross Handle bags

Bag Width: 280mm – 600mm

Bag Length: 300mm – 600mm

For Wicket Bag

Bag Width: 130mm – 420mm

Bag Length: 200mm – 420mm

Internal Perforation unit inside gusset area for air exhausting for Paramount bag

Round perforation knife for wicket bag at bottom gusset part

Air cooling system for Electrical Cabinet

Vacuum system for punching waste, including pumping system and pipes

Trimming knife with waste scrap after Folding

Cross handle unit

Max. mechanical speed: 100 pcs/min

Unwinder:

Hydraulic unwind device with electric power

Power brake with automatic tension control system by Mitsubishi

Air shaft diam. 76 mm

Film Lack sensor: machine stops when film is finished

Film broken sensor: machine stops if film breaks

Max. film weight in reel: 650 kg

Sealable film quality and thickness:

- Mother reel film (LD-PE / LLD-PE): 30 - 100 micron

- Handle strip diaper bags (LD-PE / LLD-PE): 70 - 125 micron

Unwind unit for Paramount Bag:

Max. width: 250 mm

Reel diam. 600 mm

Air shaft diam. 76 mm

Film lack sensor

Film broken sensor

Automatic tension control system

Manual brake control system

Unwind unit for Cross Handle bag:

Rolls width: 100 mm

Reel max diam. 600 mm

Film lack sensor

Film broken sensor

Automatic tension control system

Manual brake control system

2 set Hot Air sealing equipment (down sealing for Paramount bag):

Sealing drum diam. 200.7 mm

Sealing drum width: 1840 mm

Sealing length: 226 mm

2 seal heads covering 270º of the drum, each with own independent temperature control

Hot air gap: 0,4 mm

Distance between seal heads and seal drum is adjustable

Automatic lift-off of the seal head at machine stop

Heat failure alarm

Triangle Frame with Folding Equipment:

For forming a Semi-Tube

Bag length max: 600 mm

Bag length min. 200 mm

Gusset equipment:

Special top gusset unit for handle

top gusset depth: 20 - 75 mm

Hot Air sealing equipment (Top sealing for Paramount bag):

Sealing drum diam. 200,7 mm

Sealing drum width: 1290 mm

Sealing length: 226 mm

2 seal heads covering 270º of the drum, each with own independent temperature control

Hot air gap: 0,4 mm

Distance between seal heads and seal drum is adjustable

Automatic lift-off of the seal head at machine stop

Heat failure alarm

Hot Punching unit (for Paramount bag):

Punch hole for the handle (full cut-out)

Driven by air cylinder

width: 78 mm

Height: 20 mm

Punching equipment for the waste (for Paramount bag):

Shoulder cut-out

Width: 185 mm

Wicket Hole Punching equipment (for all kind of bags);

2 round punching units of 14 mm

2 vertical type perforation knife

E.P.C. Equipment

Servo motor by Yaskawa (400W)

Third wicket hole: 14 mm (a 8mm unit as spare part)

Horizontal perforation knife

Perforation Knife equipment: Tear-open perforation units for Straight line and L Shape

Cross-shaped Air Hole

Knife length max. is 1300 mm; sealing & cutting max length: 1250 mm

Wicket device for finished production: after sealing & cutting, bags come out and are collected by rolling the arms to a set of bags to conveyor device

Number of bags per stack: 30-50, up to their thickness

2 Anti-static bar before cutting

2 anti-static bar after cutting

Other Details:

Guarantee: Without guarantee

Current condition: Dismantled. Can be assembled to see running with material

Availability: Immediate

Voltage: 380 V Triphase

Frequency: 50 Hz

Voltage: 10 Kw