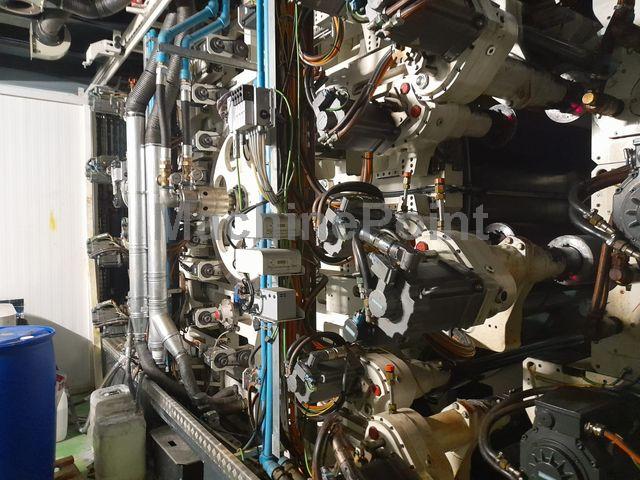

Used COMEXI OFFSET CI8 of 2014 for sale

8 Colours CI Flexo Printing Machines COMEXI, You can contact our team and analyze your needs so we can offer you the best possible solution depending on your budget.

Data Sheet of Used COMEXI OFFSET CI8

Ref.: 300045724

Year: 2014

Brand: COMEXI

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Printing Width: 1050 mm

- Web Width: 1120 mm

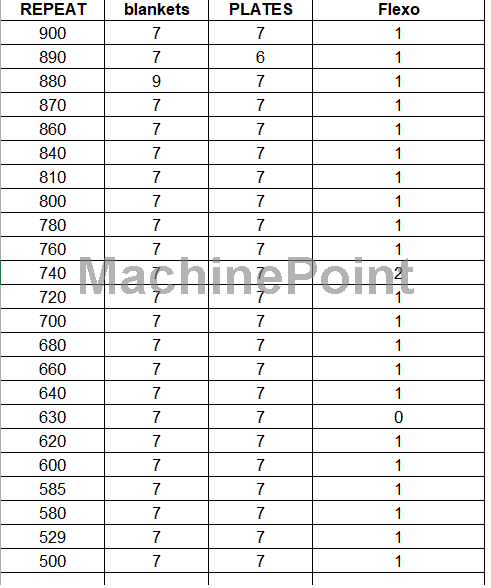

- Printing Repeat (Max): 930 mm

- Printing Repeat (Min): 455 mm

Other Specifications:

Materials :

LDPE : 20-150 microns

LLDPE : 12-100 microns

HDPE : 20-150 microns

BOPP : 12-60 microns

PET : 12-50 microns

Paper : 40-120 gr

Printing possibilities : 7 Offset units and 1 flexo unit

Inks : Electro Beam

Printing speed : up to 300 m/min

Turret unwinder for diameters up to 1000mm, with shaft system supported by blade

Min reel diameter : 500mm

Max reel weight : 1250 kg

Turret rewinder for diameters up to 1.000mm, with shaft system supported by blade.

Max. reel weight : 1250 kg

Min-max tension range : 20-350N

Electron-beam curing system

Computer controlled operating system using a Siemens S7-300 PLC system.

Profibus control register module

Webvideo Star 2000 modular inspection system

Ultrasonic cell web guiding system OPG brand BST

Technotrans AG

Semi-automatic plate bender for variable formats with optical positioning system.

Sleeve mounting station

CTP (Computer to Plate) + Plate Processor

Drum cleaner

Upper inkwell access system for easy sleeve changes with automatic sleeve change system

Corona treatment 6kW

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown with material

Availability: Immediate

Voltage: 400 V Triphase

Frequency: 50 Hz