Used BANDERA TR.100.AFT/30D of 1999 for sale

Sheet monoextrusion lines BANDERA, We will be by your side all along the process of buying your machinery, from the initial assessment, accompanying you in the visits, legal and technical consultancy, and defined contracts that will protect you.

Data Sheet of Used BANDERA TR.100.AFT/30D

Ref.: 300045792

Year: 1999

Brand: BANDERA

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Materials: PP,PS

- Film Width (Max): 950 mm

- Film Thickness (Min): 0.2 mm

- Film Thickness (Max): 2 mm

- Output Capacity: 300 kg/h

- Layers: 1

- Number Of Extruders: 1

- Screw Diameter: 100 mm

- Screw L/D Ratio: 30

- Motor Rating: 132 kW

- Heating Zones (Extruder): 5

- Heating Capacity: 92 kW

- Screen Changer: Yes

- · DIE HEAD: Yes

- Die Lip Gap: 2.5 mm

- Number Of Rolls: 3

- Roll Width: 1000 mm

- Roll Diameter: 410 mm

- Roller Cooling: Yes

- Rewind Unit Type: Double

- Rewind Roll Diameter: 1200 mm

- Rewind Roll Width: 950 mm

- Speed: 20 m/min

Other Specifications:

Dosing system included - number of components: 4

Average consumption (kW): 140.

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate

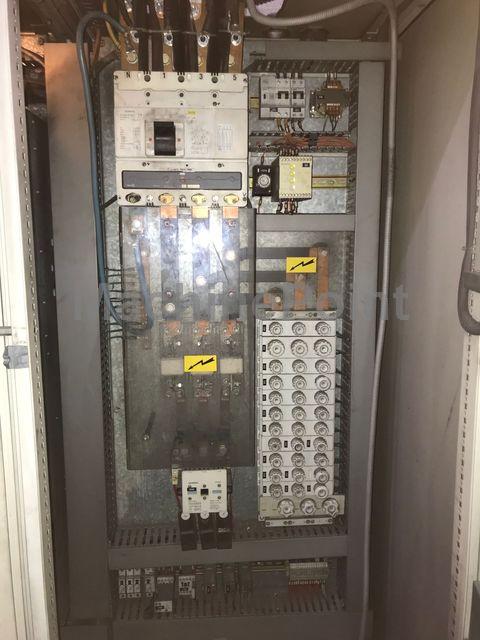

Voltage: 380 V Triphase

Frequency: 50 Hz

Voltage: 300 Kw