Used MPS EP410 of 2004 for sale

Label flexo printing machines MPS, We guarantee that the buying process for used machinery through MachinePoint is safe and professional.

Data Sheet of Used MPS EP410

Ref.: 300046151

Year: 2004

Brand: MPS

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

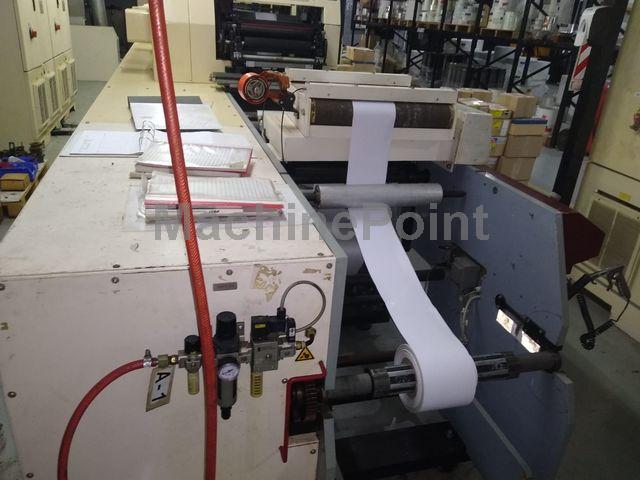

- Number Of Colours: 10

- Printing Width: 410 mm

Other Specifications:

10 full UV colors. Dual printing method, each can have flexo or screen printing, not at the same time.

Gew UV lamps

Chiller for material

Rotary Stamping

Delam Relam

4 die cutting stations (middle, and 3 at end of machine)

Cylinders

3x 122

5x 129

16x 131

1x 139

1x 146

4x 152

5x 167

8x 168

4x 178

2x 180

6x 183

5x 192

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate

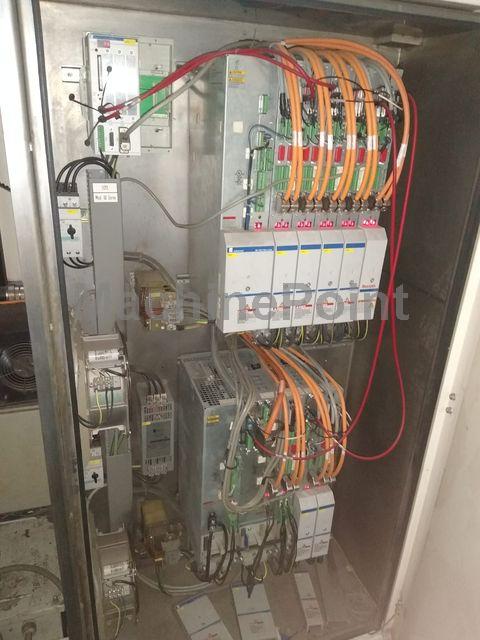

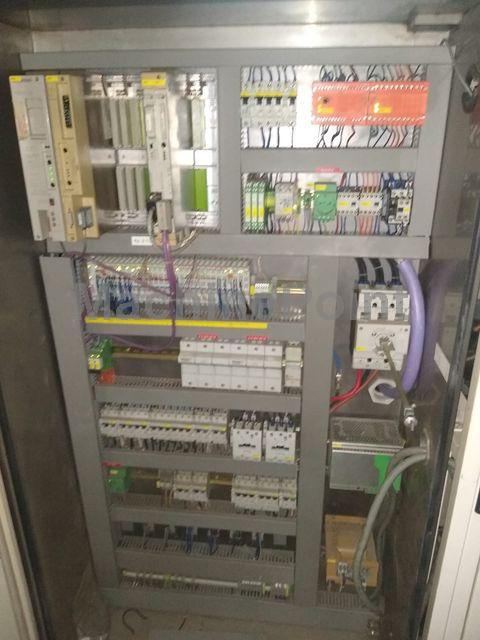

Voltage: 380 V Triphase

Frequency: 50 Hz