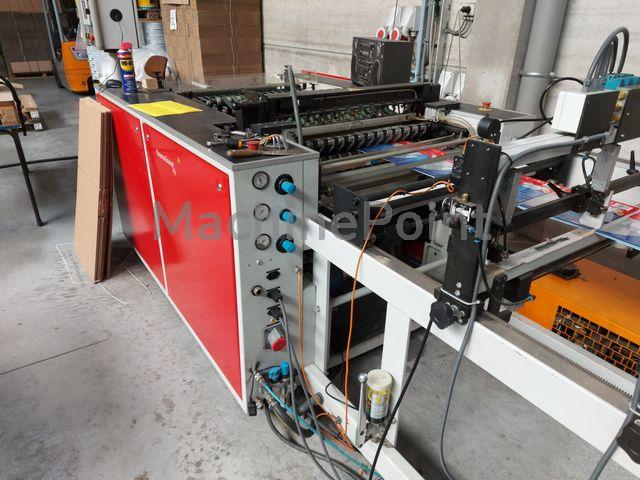

MODEL 5106 W SERVO DRIVEN WICKET BAG MAKING MACHINE

MAX. DRAW LENGTH 620MM, LEFT HAND CONFIGURATION

A/ Machine Capabilities

Draw length (bag width) : 150 - 620mm

Seal width (bag height) : 240 – 1015mm* (without attachments) // 240 – 915mm* (with servo attachments)

* Maximum bag length can only be achieved by adding a third wicket arm and drape bar and can be limited by the width of the unwind.

Actual speeds depend on material quality, gauge and seal ability, bag dimensions and style, operator experience, etc…

Seal strength will reduce at treatment levels of 38dynes/cm and above.

Mechanical cycle speed:350 cpm

Bag styles:

·Simple diaper bag without handle

·Paramount style diaper bags with longitudinal seal inside the gusset, sealed handle on the top

·Paramount style diaper bags with longitudinal seal outside the gusset, sealed handle on the top

·Diaper bags with a folded strip foreseen of slits

·Diaper bags with a single strip

Material:

Basic bag film : 18-120µ

B/ Surface Driven Single Roll “Shaftless” Reel Lift Unwind Stand 1.770mm

max. roll width : 1.770mm

min. roll width : 400mm

max. reel dia. : 1.000mm

max. weight : 1.000kg

max. speed : 120m/min

C/ Folding Triangle 2.000mm

D/ Tip Gusset Former

min. gusset depth : 20mm

max. gusset depth: 150mm

5 Dimensions included (20mm, 60mm, 100mm, 120mm and 150mm)

E/ Continuous ball & die punch

Throat depth: Max 60mm

F/ Trimmer

Min. trim width: 10mm

Max. trim width: 25mm

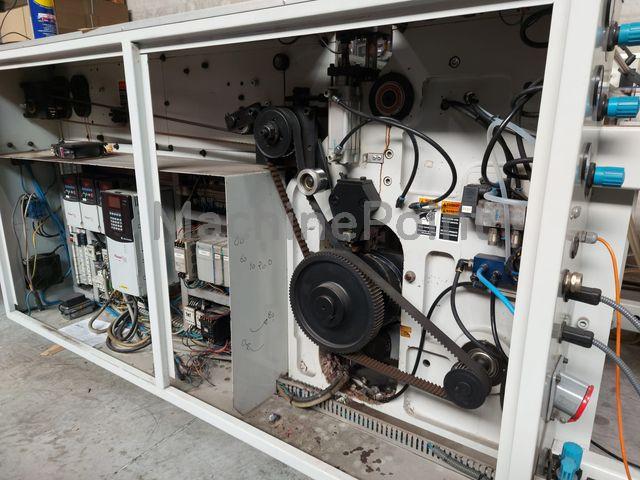

G/ Auto Correction System (Patented)

Automatic positioning of all attachments (photo eye, wicket punch, pre-sealer, dual static loader, etc…) to accommodate print repeat variations

G.2. Seal Bar Cleaner

H/ Attachments

H.1. Two level Static Loader

H.2. Moveable Mid-feed anti-bounce rolls

H.3. Servo Driven Wicket Punch 600mm

H.4. Servo Driven Pre Sealer 200mm

H.5. Conversion Kit For Pre Sealer into a “Chevron” Sealer

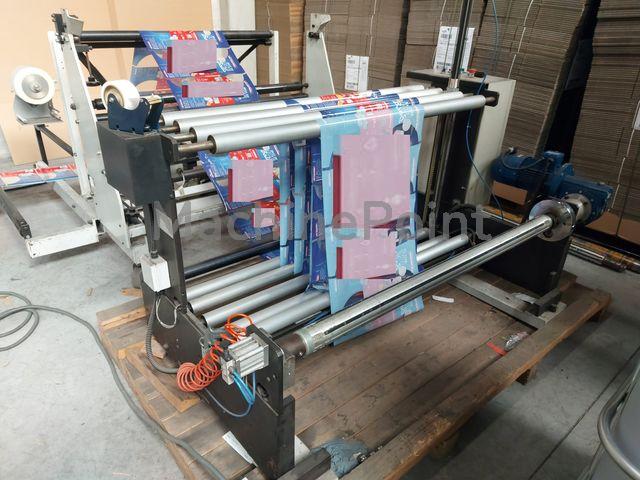

I/ Automatic "ONE STEP" Wicket Stacker With 1 Stacking And 8 Unloading Positions 620mm

J/ EQUIPMENT TO PRODUCE “PARAMOUNT” STYLE BAGS SEALED INSIDE OR OUTSIDE

J.1. Add-on Film Unwind And Inserter For “Paramount” Handle Film (350mm)

1. For rolls of max. 350mm wide, max. Ø700mm

2. Electric shaft driven and braked

3. Turret unwind with an expandable shaft for Ø76 (±2)mm ID cores, max. deflated dia. of the shafts 74mm

4. End of reel and film break detection

5. Edge guiding with one ultrasonic sensor

6. Slitter to split the handle film into 2 handle films

7. Lane movers to position the 2 handle films with manual position adjustment

8. Static loader to fix the handle films to the main film

J.2. Contact Longitudinal Sealer 2.000mm

1. Two seal units

2. Seal unit consists of 2 top-bottom sealing blocks and 1 top-bottom cooling block (water cooled, to be supplied by customer); 1500 Watt per seal head

3. Independent temperature control

4. Cross adjustment of the seal heads by spindle

5. Teflon band driven by main film

6. Automatic lift-off of the seal head at machine stop

7. Heat failure alarm

8. Max. film width : 2.000mm

9. Min. film gauge : 30µ

10. Seal width : +- 2mm

J.3. Additional Tension Control Unit 2.000mm

J.4.Overstep Platform 2.000mm

J.5. Vertical Gusset former And Unfolder For “Paramount” Handle Film Sealed on the Outside of the Gusset

min. gusset depth : 40mm

max. gusset depth: 100mm

J.6. Unfolder For “Paramount” Handle Film Sealed on the Inside of the Gusset

J.7. Contact Longitudinal Sealer 1.000mm

1. One seal units

2. Seal unit consists of 2 top-bottom sealing blocks and 1 top-bottom cooling block (water cooled, to be supplied by customer); 1500 Watt per seal head

3. Independent temperature control

4. Cross adjustment of the seal heads by spindle

5. Teflon band driven by main film

6. Automatic lift-off of the seal head at machine stop

7. Heat failure alarm

8. Max. film width : 1.000mm

9. Min. film gauge : 30µ

10. Seal width : +- 2mm

J.8. Servo Driven Handle Cut Out Clean Cut (in longitudinal direction)

J.9. Servo Driven Shoulder Cut Out

1. Min. cut-out 140mm

2. Max. cut-out : 400mm

3. Radius : 45mm

4. Servo driven, max. cycle speed 125CPM

5. Flying knife

J.10. “Double” Easy Dispensing Perforation

1. Pneumatic driven

2. Equipped with two perforation pattern, length 250mm:

-2 knives straight 1mm cut / 2mm land

-2 knives straight 2mm cut / 5mm land

3. Max. width 100mm

4. Double knife design

5. Film clamping during cutting

6. Position adjustable on the fly

7. Max. mechanical cycle speed: 240CPM

8. Automatic positioning in cross direction

K/ EQUIPMENT TO PRODUCE FOLDED AND FLAT STRAP HANDLE BAGS

K.1. Add-on Film Unwind For Inserted Tape (100mm)

1. For rolls of max. 100mm wide, max. Ø700mm

2. Electric shaft driven and braked

3. Turret unwind with an expandable shaft for Ø76 (±2)mm ID cores, max. deflated dia. of the shafts 74mm

4. End of reel and film break detection

K.2. Tape Preparation And Insert System For Folded and Flat Strap Handle