Used BENCO PACK ASEPACK/12 C-S of 2007 for sale

Cup Form-Fill & Seal machines BENCO PACK, We will be by your side all along the process of buying your machinery, from the initial assessment, accompanying you in the visits, legal and technical consultancy, and defined contracts that will protect you.

Data Sheet of Used BENCO PACK ASEPACK/12 C-S

Ref.: 300032962

Year: 2007

Brand: BENCO PACK

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Output: 18000 U/h

- Cup Volume (Min): 125 g

- Cup Volume (Max): 125 g

- Material Width: 393 mm

- Hygienic Standard: Aseptic

Other Specifications:

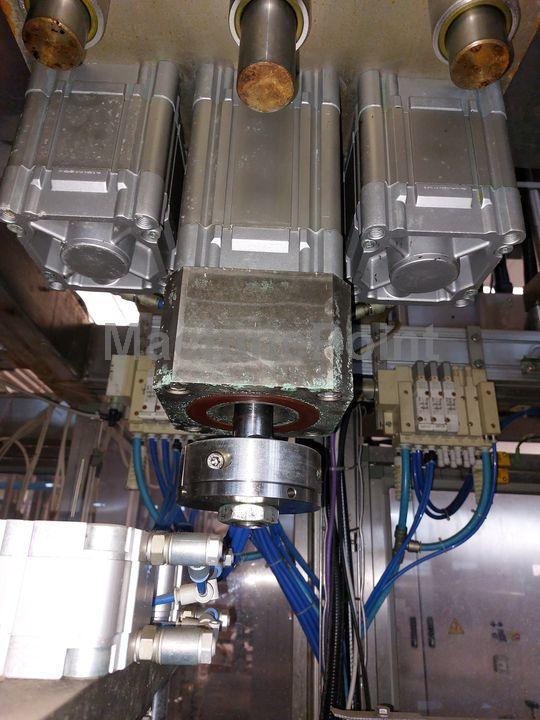

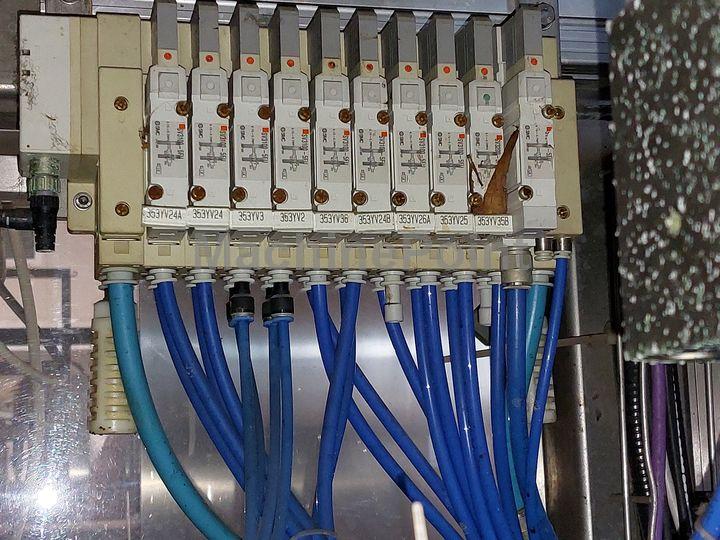

Aseptic Cup Form, Fill and Seal machine Bencopack ASEPACK/12 C-S, year 2007

Including sterilizer FBR-ELPO and packaging machine KLIKLOK

Nominal working speed: 25 cycles/min

Machine performance: depending on the products; products’ characteristics; packaging materials (dimensions, tolerances, thickness, composition, machinability)

Number of thermoformed cups/cycle: 12

Forming area: 6x2

Cup capacity: 125 ml

Cup dimensions: 63x63 mm

Plastic and lid film web width: 393 mm

Type of cut: without intermediate material scrap

Cutting configuration*: multipacks (2x2) and multipacks (2x1)

Materials usable for the cup bottom: PS and PS-based multilayer material

Materials usable for the cup lid: AL, AL+PET

The machine has approx. 400 working hours! Disconnected, but still in the production hall. Out of use since 2015.

Other Details:

Guarantee: Without guarantee

Current condition: Disconnected. Can't be seen in running condition

Availability: Immediate

Clasification:

Final Products: Yoghurt, Dessert

Used Materials: Cups

Processes: Filling

Application: Aseptic