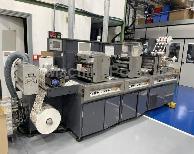

Used ABG DIGICON SERIES 2 of 2010 for sale

Label sheeter - cross cutting ABG, MachinePoint offers their clients all the services necessary to buy the machine: Transport, dismantling, and legal consultancy.

Data Sheet of Used ABG DIGICON SERIES 2

Ref.: 300035130

Year: 2010

Brand: ABG

Delivery time: From date

Ask for machine price Want to sell your machine?

Technical Specifications:

Other Specifications:

1 flexo varnishing unit

1 rotary diecut unit K & B GAPMASTER

Maximum roll diameter unwinder : 700mm

320 W x 305 L maximum print hot foil area

320 W x 300 L maximum die cut area

Maximum running speed at 300mm repeat : 36m/min

Minimum plate cylinder flexo 10” (254mm)

Maximum plate cylinder flexo 24” (609mm)

Maximum rewind diameter single shaft : 600mm

No hot foil unit

Web guide

No corona treatment

No lamination

It’s a modular semi rotary machine rotary die cutting and varnishing

Any other stations can be added since it is a modular machine

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: From date