Used ILLIG FS37 of 2019 for sale

Cup Form-Fill & Seal machines ILLIG, We will be by your side all along the process of buying your machinery, from the initial assessment, accompanying you in the visits, legal and technical consultancy, and defined contracts that will protect you.

Data Sheet of Used ILLIG FS37

Ref.: 300044762

Year: 2019

Brand: ILLIG

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Output: 12000 U/h

- Cup Volume (Min): 35 g

- Cip: Yes

- Sip: Yes

Other Specifications:

Cup form, fill and seal machine Illig FS37, year 2019 for cream cheese

APET container with ALU lid materials

Output: 12,000 packs per hour.

Volume: 35 g

Cup size: 135 x 51 x 23 mm

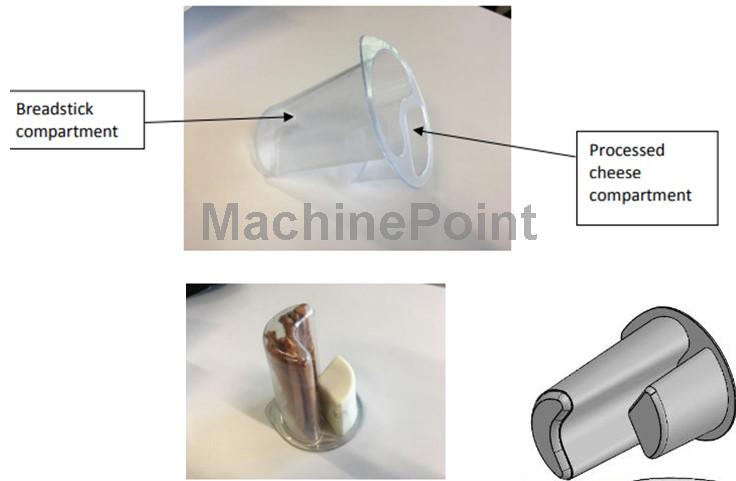

Cups with two compartiments: breadstick & cream cheese

Maximum forming area: 375 x 350 mm.

Format layout: between 10 and 32 packs per cycle

Servo-driven form, with Siemens S7 with SOFT PLC on industrial PC (Windows) Touchscreen control panel with color display and Bosch Rexroth MLC;

User interface language and documentation : German or English

Machine in right-hand version. Operating direction from left to right

1 heater carriage. Heater length max. 1.200mm

Special length of filling range 6466, self-supporting version, with separation for simple in-house transport

Guides and format parts for special filling range 6466 mm, incl. fixed and movable grippers

ILLIG NetService can be activated for online remote diagnosis and maintenance of all machines with Ethernet-connected components.

Includes:

- Cooling device PC 125.24b

- Additive for coolant treatment

In production until mid-January 2023.

Available immediately.

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate

Clasification:

Final Products: Soft cheese

Used Materials: Cups

Processes: Filling

Application: Clean