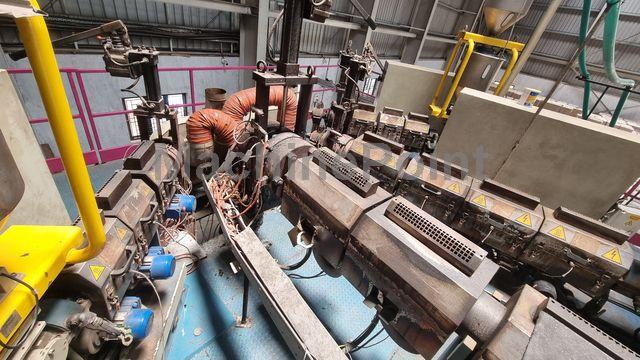

Used ADTECH PROVERA Coex of 2006 for sale

Stretch film extrusion line ADTECH PROVERA, We provide a quality service in the buying and selling of used machinery, with all the services necessary to achieve a successful transaction.

Data Sheet of Used ADTECH PROVERA Coex

Ref.: 300045719

Year: 2006

Brand: ADTECH PROVERA

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Layers no.: 5

- Web Width: 1000 mm

Other Specifications:

Five layer coextrusion line with four extruders.

GENERAL

Thickness range : 10 – 50 mic

Net output : 450 kg/h

The Material to be processed -- LLDPE and mLLDPE, Vistamaxx, PIB

Machine speed -- 600 m/min

EXTRUDERS

Each extruder is having one individual hopper with automatic vacuum loader.

Ext A – Screw dia – 45 mm, L/D Ratio - 30

Ext B – Screw Dia – 120 mm, L/D Ratio -- 30

Ext C – Screw Dia – 70mm, L/D ratio – 30

Ext D – Screw Dia – 45 mm, L/D Ratio – 30

All extruders are having hydraulic screen changers

DIE - from OEM

Die slot width -- 1500 mm

Flex lip opening range – 0.5mm to 1.5 mm

Die bolt span -- 30mm , No. of die bolts – 50

Equipped with dual chamber vacuum box – Overall width 1500 mm

It is an automatic die. But, right now it is working in manual mode with +/- 5% thickness variation with uniform and excellent reel profile

Contains 2 nos of Electrostatic edge pinning devices

CHILL ROLL

Chill roll face width – 1650mm, Diameter – 1000 mm,

Secondary chill roll face width – 1650mm, Diameter – 450 mm

AUXIALIARY UNIT

Consists of one adjustable stroke Oscillating unit.

Consists of edge trim in line reprocessing system

SCANNER FOR ONLINE THICKNESS MEASUREMENT

X-Ray scanner from Scantech

WINDER

Core automatic feeder.

4 shaft automatic turret winder with web tension measurement and web separation – Finished roll diameter – 80 to 250 mm, Cardboard (core) inner diameter – 2” and 3”.

Refurbishment details --- The line is completely refurbished to run the line smoothly.

a) All the drives of extruder A, B, C and D, drives of haul off units, drives of dosing unit and feeder unit replaced with new drives.

b) Chill roll inlet pipe (which pours water into the chill roll drum) was made new to get efficient and uniform cooling.

c) All new silicon rubber roll made to clean the chill roll so that the film is free of waxes.

d) Old scanner unit was replaced with the new scanner from scantech.

f) Some of the extruder zones were changed from infra-red heaters to band heaters.

g) Lot of pneumatic pipes were replaced with new pipes.

h) Old contactors and faulty MCBs were replaced.

j) Main extruder Panel AC and Scanner panel ACs are serviced.

l) Faulty Panel cooler fans replaced.

Optional

60TR chiller from Prasad Koch technik (Price on request)

Other Details:

Rebuild: 2021

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate

Voltage: 415 V Triphase

Frequency: 415 V Triphase

Voltage: 450 Kw