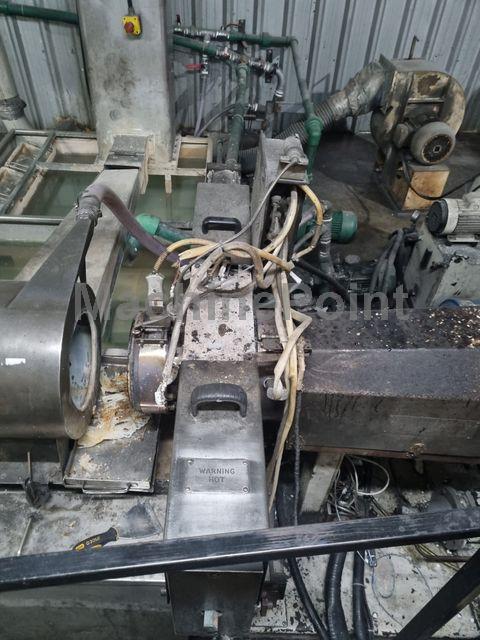

Used MUNCHY P75 A of 1996 for sale

Single screw repelletizing line MUNCHY, MachinePoint has a multicultural team with world presence to be able to be closer to our clients. We speak over 15 different languages.

Data Sheet of Used MUNCHY P75 A

Ref.: 300045873

Year: 1996

Brand: MUNCHY

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Screw Diameter: 75 mm

- Output Capacity: 90 kg/h

- Degassing System: No

- Heating Power (Extruder): 45 kW

- Suitable Material Form: Film

- Type Of Screen Changer: Hydraulic

Other Specifications:

Materials processed: HDPE and LDPE

Origin of materials processed: Internal Scrap

Reel feeder

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate