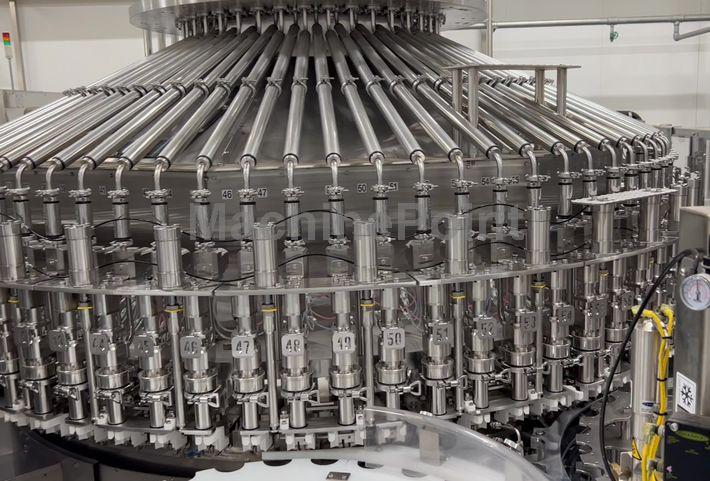

Used MITSUBISHI FHRJ80M24 of 2017 for sale

Dairy bottling Line MITSUBISHI, We will be by your side all along the process of buying your machinery, from the initial assessment, accompanying you in the visits, legal and technical consultancy, and defined contracts that will protect you.

Data Sheet of Used MITSUBISHI FHRJ80M24

Ref.: 300046612

Year: 2017

Brand: MITSUBISHI

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Output: 40000 U/h

- Bottle Size: 295ml, 390ml

- Valves-Filling Heads: 80

Other Specifications:

Complete MITSUBISHI Hot Filling Line for Aluminum Bottles, Year 2017.

Capacity: 40,000BPH

Used to fill black or milk coffee

Aluminium bottle sizes: 295ml and 390ml

Number of Filling Heads: 80

Includes:

- Filler Rinser Capper

- Visual inspection machine

- Bottle pressure checker

- Mixer

- Conveyors

Running hours: Around 3,400

Machine available immediately!

Other Details:

Guarantee: Without guarantee

Current condition: Dismantled. Can't be seen in running condition

Availability: Immediate

Clasification:

Final Products: Milk

Processes: Filling

Application: Extended Shelf Life (cold chain), Hot Filling