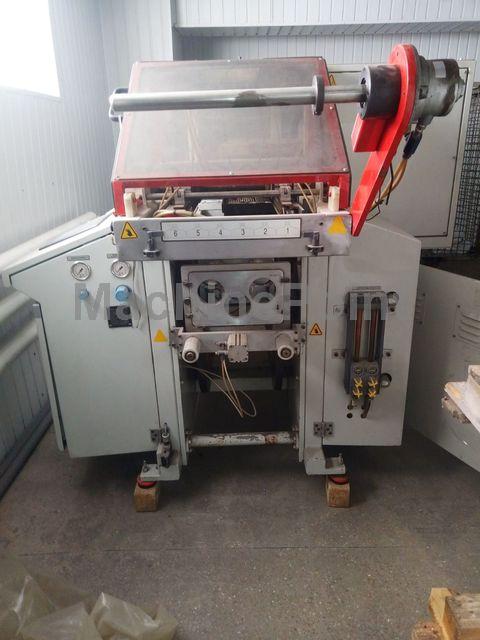

Used GN 1407TM of 2005 for sale

Thermoformer GN, You can contact our team and analyze your needs so we can offer you the best possible solution depending on your budget.

Data Sheet of Used GN 1407TM

Ref.: 300042024

Year: 2005

Brand: GN

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Material : PP PET, HIPS, PVC, ABS, PS, OPS

- Forming Area (Vxh): 320x180

- Depth Of Draw: 120 mm

- Material Thickness (Min): 0.35 mm

- Material Thickness (Max): 2 mm

- Products Type: Lid

- Feeding Systems: Roll fed

Other Specifications:

This machine is designed to produce termoforming moulded products with a pre-punch streching of material. Moulding and cutting of finished products is performed in one unit, which ensures accuracy and repeatability of products throughout the entire production process. After molding and felling, the molding unit rotates and pushes the finished products onto a receiving stacker.

Forming depth (negative / positive): 120 mm - 25 mm

Material width maximum: 350 mm

Maximum roll diameter: 1000 mm

Roll maximum weight: 250 kg

Dry cycles max. : 35 1/min

Maximum air consumption: 1.25 m3/min

Operating air pressure: 7 kg/cm2

Water consumption: 780 l/hour

Heat quantity to be dissipated: 0.75 KW

Average power consumption: 7 KWh

Air consumption: 1.25 m3/min

Plug-Assist

The machine is supplied with a 98.5 mm diameter mould for the production of polystyrene caps for D=95 mm PS glasses. The form is 3-place with V - shaped arrangement of cells. Also included in the set is a stacking tool for finished products.

7000 working hours.

The machine has been working for only one year.

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown in dry cycle

Availability: Immediate

Voltage: 440 V Triphase

Frequency: 50 Hz

, Frequency: 60 Hz

Voltage: 45 Kw