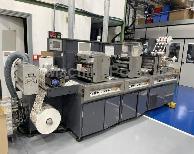

BERRA - SF 330

Label Screen Printing machines. Material 340 mm Dimensions max 330 x 350 mm Unwinder 4 Screen colours 1 Flat hot foil 1 Semi-rotary Hot Foil 1 semi-rotary die cut 1 Rewinder + slitting ...

2013 | 300046833 | BERRA

Label Screen Printing machines. Material 340 mm Dimensions max 330 x 350 mm Unwinder 4 Screen colours 1 Flat hot foil 1 Semi-rotary Hot Foil 1 semi-rotary die cut 1 Rewinder + slitting ...

2013 | 300046833 | BERRA

Label Screen Printing machines. Printing length min 96 mm Printing length max. 192 mm...

2012 | 300042374 | STORK

J.M. ASSOCIATS CENTRE Tecno

Label Inspection Machine

Do you need advice?

We will guide you through the entire process of buying and selling used machinery in a changing and complex international environment. Our sales, logistics, legal, and marketing teams will accompany you throughout the process to make the operation easy and risk-free.