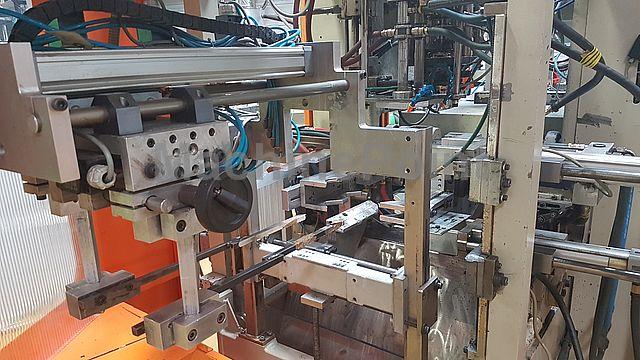

Used BATTENFELD FISCHER VK 1-1 of 1989 Container Size With Actual Configuration: 0.3 l for sale

Extrusion Blow Moulding machines up to 2 L BATTENFELD FISCHER, We guarantee that the buying process for used machinery through MachinePoint is safe and professional.

Data Sheet of Used BATTENFELD FISCHER VK 1-1

Ref.: 300042451

Year: 1989

Brand: BATTENFELD FISCHER

Delivery time: 1 - 2 months

Ask for machine price Want to sell your machine?

Technical Specifications:

- Container Size With Actual Configuration: 0.3 l

- Number Of Heads: 2

- Material Type: PE

- Number Of Stations: 1

- Extruder Type: Continuous

- Number Of Extruders: 1

- Screw Diameter: 50 mm

- L/D: 20

- Wall Thickness Control: MOOG

- Center Distance: 100 mm

Other Specifications:

Extrusion Blow molder Battenfeld-Fischer VK 1-1

Year 1989

Two-head

Center distance 100 mm

Hot knife

Deflashing unit

MOOG parison thickness control 25 points

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: 1 - 2 months

Voltage: 380 V Triphase

Frequency: 50 Hz

MachinePoint's services:

Loading and lashing

Packaging

Dismantling

Extra products and services for extrusion blow molding machines

Moulds for Injection Stretch Blow moulding machines

Extrusion Heads for Blow Moulding extrusion machines

Refurbishing & Overhauling services

Used Machinery Appraisals

Transport of industrial machinery