Used ALPINE 4 HXS 50-30D / 1 HXS 75-30D of 2018 for sale

Coextrusion lines ALPINE, We provide a quality service in the buying and selling of used machinery, with all the services necessary to achieve a successful transaction.

Data Sheet of Used ALPINE 4 HXS 50-30D / 1 HXS 75-30D

Ref.: 300045449

Year: 2018

Brand: ALPINE

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Materials: LDPE, LLDPE, MLLDPE, regenerated

- Film Width (Max): 1600 mm

- Output Capacity: 450 kg/h

- Number Of Extruders: 5

- Layers: 5

- Rewind Unit Type: Back to back

Other Specifications:

The line did not process pure HDPE in 5 layers; 1 to 2 layers are possible with LDPE.

For the rest of the materials: LDPE, LLDPE, MLLDPE, regenerated.

Capacity: 400 to 450 kgs of maximum output depending on the width and thickness.

The machine can make shrink film.

The height of the haul off is 16 -17 meters

5 extruders

4 x HXS 50-30D

Screw diameter : 50mm

Screw length: 30 L/D

Heating zones: 5

1 x HXS 75-30D

Screw diameter: 75mm

Screw length: 30 L/D

Heating zones: 5

Magnetic separator

CONTROL OF THE INSTALLATION :

Process control ExVis 4.0

One Touch

Manually operated screen changer, batch operation

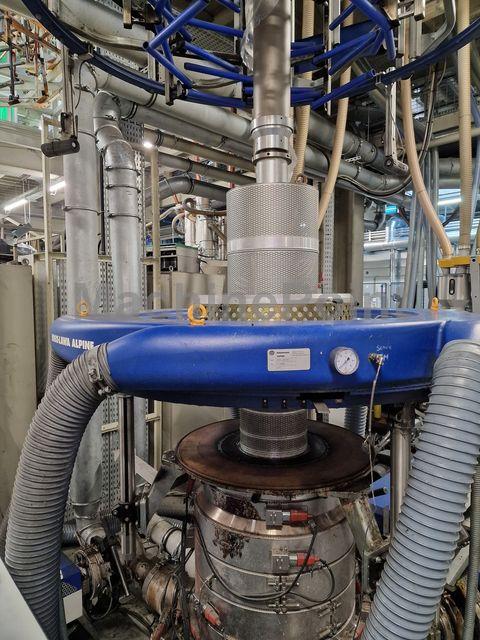

BLOWER HEAD:

FBF 16-40X, Coex 5 layers,

Helical blowing head for 5-layer films, with ABCDE layer composition

Die diameter: 200mm

Die diameter range: 160-400mm

Outside diameter: 660mm

Temperature setting range: 5

EXTERNAL COOLING with height adjustment for cooling the bubble on the outside :

Cooling ring type CR

Fan designed as a radial fan

Frequency converter for speed control

Electrical height adjustment

Die diameter range: up to 400mm

Fan power: 18.5 Kw

INTERNAL COOLING :

AIC VX with BDC bubble adjustment

BDC bubble adjustment unit with :

3 ultrasonic sensors to capture the diameter of the duct

BDC software

Parameter input and monitoring via touch screen of the ExVis process visualization system

Cooling tower type IBC-VX

Incoming air fan with noise damper

Exhaust air fan

Frequency inverter for each fan for speed control

Power of the incoming/outgoing air fan: 11 Kw

CALIBRATION BASKET :

8 arms with rollers on ball bearings

5 levels of rollers

Electrical adjustment of diameter and height

Supporting elements for fixing the ultrasonic sensors of the bubble adjustment

Flat width min-max: 530mm-2360mm

Height adjustment range up to 1500mm

Additional basket

8 arms with rollers on ball bearings

2 roller levels

Electric diameter adjustment

Flat width min-max : 520mm-2385mm

PROFILE MEASUREMENT

PROFILE OPTIMIZATION : Number of adjustment zones: 60

HAUL OFF

Reversible pulling system, rotating frame.

Maximum flat width: 1600mm

Max. pulling speed : 150 m/min

Lateral folding unit, possible gusset 450mm

Wooden rods in the flattening unit

S-Wrap-1, second cylinder with S-wrap

Temperature control unit

2 web guide BST

Pretreatment Corona AFS

REWINDER

Film winder with two winding and pre-stretching stations, equipped with an electric motor driven roll pressing device.

Contact, contact/central and air gap winding.

Maximum speed: 150m/min

Winding shaft diameter: 3" or 6".

Max reel diameter: 1000mm

Lateral cutting unit in the pre-drawing

Longitudinal cutting unit in the pre-drawing unit

2 Longitudinal cutting units in the winder

3 additional rip knives

2 winding directions right and left

2 Soft-Nip rollers

2 winding shaft handling systems

2 laser positioning of the mandrels

4 steel 3" winding shafts

4 x 6" steel winding shafts

REEL HANDLING

There are arms that tilt to place the reel on the pallet.

There is also an x-arm to position the bar that is waiting on the next reel.

MATERIAL FEEDING (NOT INCLUDED) :

The material feeding is done by robots tshritters, it is not part of the line, it is not for sale.

The line can be fed by rods, tshritters or other robots.

PLASTCONTROL DOSING UNIT

Controlled by screw:

A : 7 dosing units

B : 5 dosing units

C : 7 dosing units

D : 5 dosing units

E : 7 dosing units

PROCESS AIR/WATER COOLING UNIT

1 heat exchanger 55

1 heat exchanger 75

ACCESSORIES :

14 deflection cylinders, flat width: 1600mm

1 edge suction at the pre-drawing

Tower not included

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate