Used EREMA Intarema 1714_TVEplus of 2014 for sale

Single screw repelletizing line EREMA, The team at MachinePoint will accompany you through the whole process of buying the machine.

Data Sheet of Used EREMA Intarema 1714_TVEplus

Ref.: 300045628

Year: 2014

Brand: EREMA

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Screw Diameter: 140 mm

- Output Capacity: 1300 kg/h

- Type Of Die Head: Die-face

- Suitable For Processing (Material): LDPE, LLDPE, HDPE, PP

- · SCREEN CHANGER: LF_2_350

Other Specifications:

HDPE : 900-1200 Kg/h

LDPE/LLDPE : 1000-1300 Kg

PP

Conveyor belt FB_10000_1200_SH

Inner width of the belt : 1150 mm

Usable conveyor length : 9900 mm

Max. load by conveyor belt : 200 kg

Drive power : 1.5 kW

Belt speed : 4.7 m/min

Weight with metal detector : approx. 2180 kg

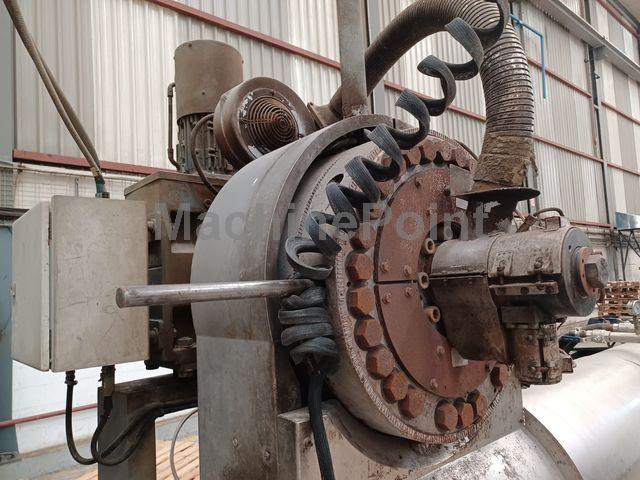

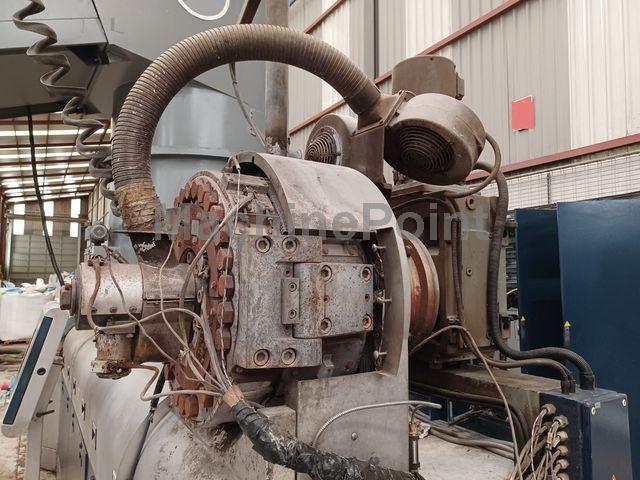

Process combination I_1714_TVEplus

Shredder drive : 315 kW

Gate: 0.12 kW

Extruder drive : 315 kW

Heating capacity zone 1 cylindrical zone (ZZ-1) : 13,2 kW

Heating capacity zone 2 cylindrical (ZZ-2) : 8,80 kW

Heating capacity zone 3 cylindrical (ZZ-3) : 10,90 kW

Heating capacity zone heating zone of plug (VEZ) : 2,70 kW

Heating capacity zone 4 cylindrical (ZZ-4) : 15,50 kW

Heating capacity zone 5 cylindrical (ZZ-5) : 9,90 kW

Heating capacity zone 6 cylindrical (ZZ-6) : 8,80 kW

Heating capacity zone 7 cylindrical (ZZ-7) : 8,80 kW

Heating capacity adaption zone (AZ-1) : 3,40 kW

Cooling pump : 1,10 kW

Vacuum pump : 4,30 kW

Total weight : approx. 20700 kg

Laser filter LF_2_350

Drive : 4,00 kW

Heating capacity of laser filter zone 1 (LFZ-1) : 2,70 kW

Heating capacity of laser filter zone 2 (LFZ-2) : 4.70 kW

Heating capacity of laser filter zone 3 (LFZ-3) : 7.22 kW

Heating capacity of laser filter zone 4 (LFZ-4) : 4.30 kW

Heating capacity of laser filter zone 5 (LFZ-5) : 5.50 kW

Heating capacity - Discharge zone 1 (LFZ-6) : 0,87 kW

Cooling fan - Discharge zone 1 (LFZ-6) : 0,36 kW

Heating capacity - Discharge zone 2 (LFZ-7) : 0,62 kW

Cooling fan - Discharge zone 2 (LFZ-7) : 0,36 kW

Max. operating temperature : 300 °C

Max. permissible mass pressure : 400 bar

Dust extraction SAS_2500

Ventilation capacity : max. 3000 m3/h

Drive power : 1,50 kW

Weight : approx. 174 kg

Service water tank BWB_500_500_S

Tank volume : approx. 420 l

Drive power of the water pump : 0,25 kW

Weight : approx. 155 kg

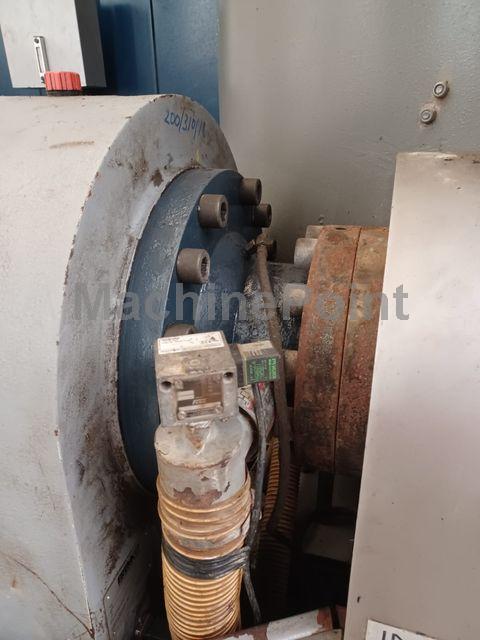

Hot cutting pelletizing head HG_244D

Number of pelletizing blades : 4

Revolutions per minute of the knife head (50Hz) : 1420 rpm

Drive power of the knife head : 2,20 kW

Pelletizing zone heating capacity (GZ-1) : 4,30 kW

Max. working temperature : 300 °C

Max. permissible melt pressure : 160 bar

Granulate dewatering screen GS_2010_1000

Vibrating screen dimensions : 1900 x 700 mm

Lump separation : < 20 mm

Tank volume : 630 l

Drive power of vibrating motors : 2 x 0.30 kW

Weight of the water separating screen : approx. 360 kg

Condition of the water pump WPS_700

Driving power of the water pump : 5,50 kW

Weight: approx. 245 kg

Granule centrifugal dryer GZ_1000_M15

Drive power : 15 kW

Weight : approx. 616 kg

Conveyor blower FG_40

Ventilation capacity : max. 2600 m3/h

Drive power : 3,0 kW

Weight + soundproofing : approx. 123 kg

Vertical Silo & Big Bag station included

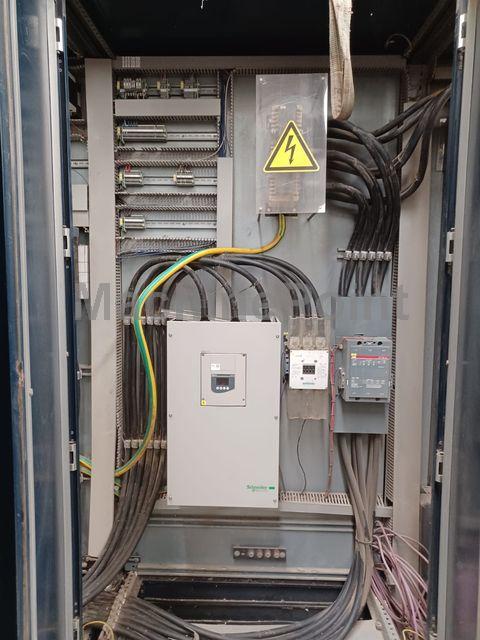

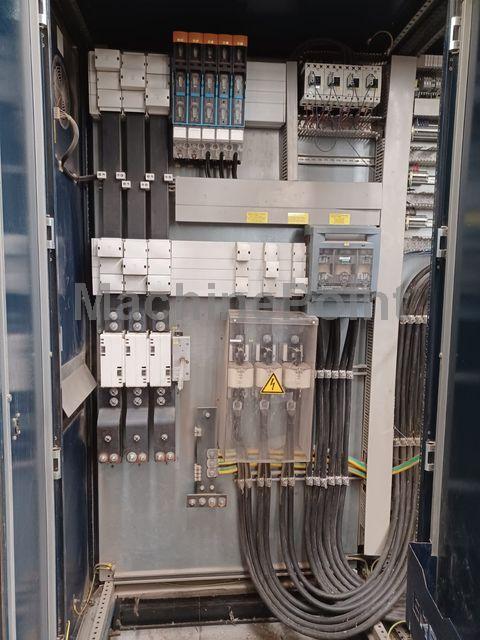

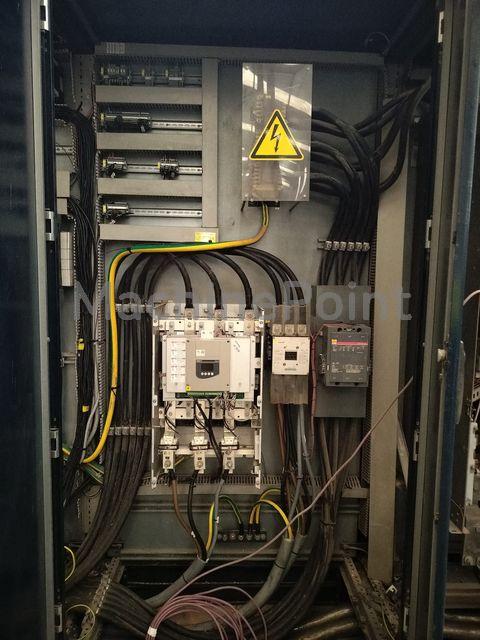

The entire electrical and mechanical part of the extruder was overhauled and new screws and gears were ordered.

The machine is delivered with new rear screw, new intermediate assemblies (sprockets) and renewed front screw.

The engine part is delivered with all the engines overhauled and with the bearings changed and the gearbox also overhauled.

Invoice and reports of everything can be delivered.

Other Details:

Guarantee: Without guarantee

Current condition: Dismantled. Can't be seen in running condition

Availability: Immediate

Voltage: 400 V Triphase

Frequency: 50 Hz