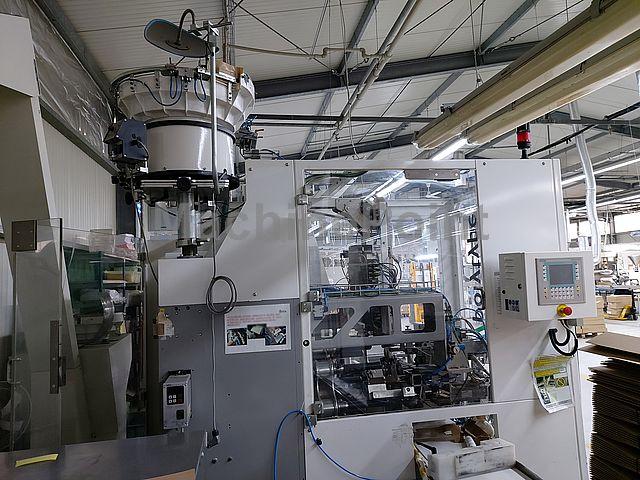

Used POLYTYPE CM 130 of 2015 for sale

Header/Capper for cosmetic tubes POLYTYPE, MachinePoint chooses the best machinery on sale in the market and we offer our clients a selection of high quality machinery.

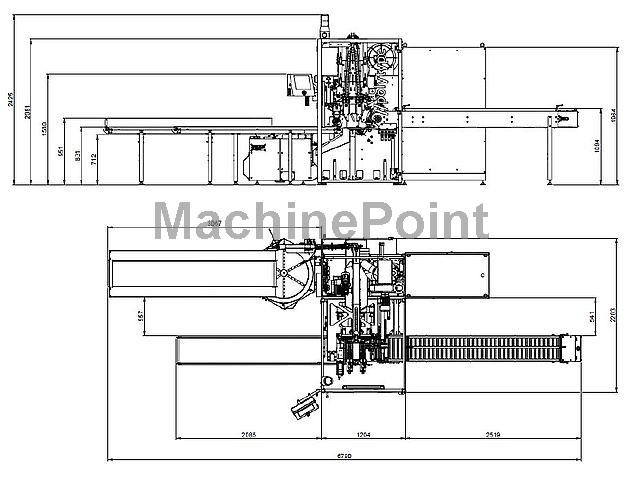

Data Sheet of Used POLYTYPE CM 130

Ref.: 300046315

Year: 2015

Brand: POLYTYPE

Delivery time: Immediate

Ask for machine price Want to sell your machine?

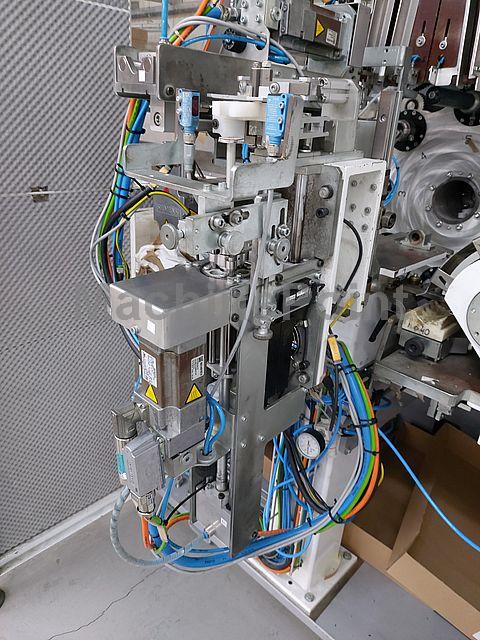

Technical Specifications:

- Tube Diameter (Min): 19 mm

- Tube Diameter (Max): 50 mm

- Tube Length (Min): 50 mm

- Tube Length (Max): 215 mm

Other Specifications:

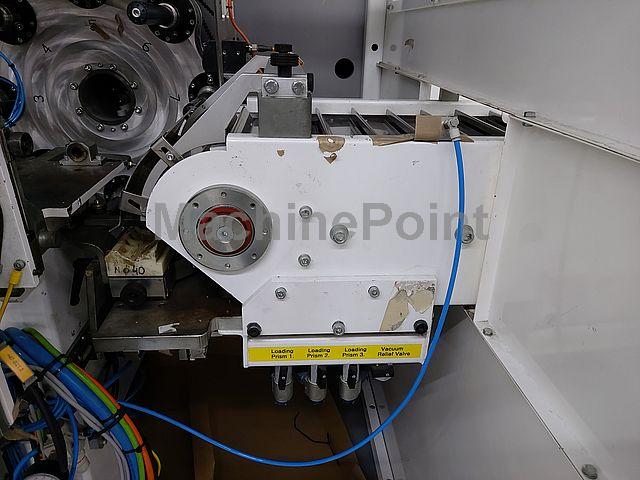

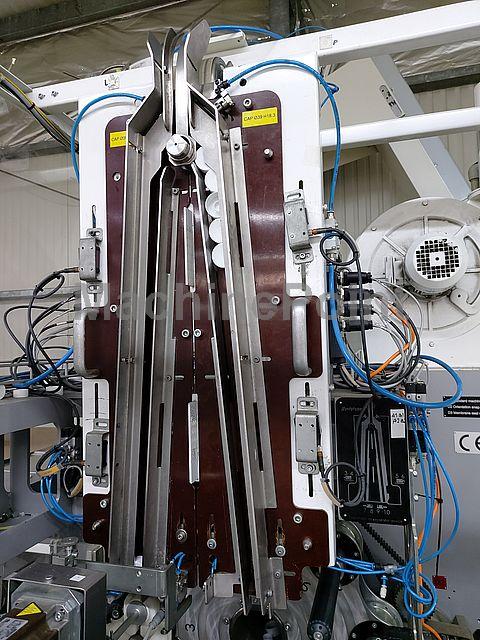

Polytype CM 130 capper

Tooling included for 19, 25, 30, 35 and 40 mm (only screw on)

Other Details:

Guarantee: Without guarantee

Current condition: Not running. Can be shown in dry cycle

Availability: Immediate

MachinePoint's services:

Loading and lashing

Packaging

Dismantling

Extra products and services for extrusion blow molding machines

Moulds for Injection Stretch Blow moulding machines

Extrusion Heads for Blow Moulding extrusion machines

Refurbishing & Overhauling services

Used Machinery Appraisals

Transport of industrial machinery