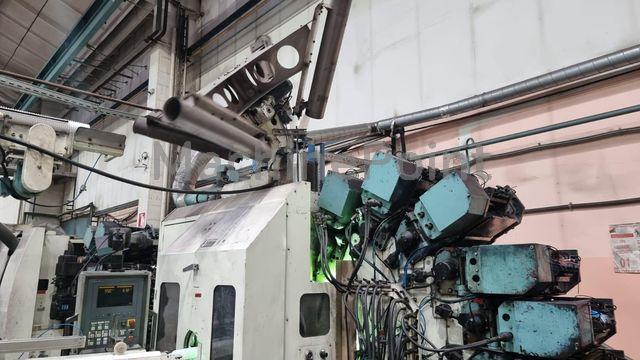

Used VAN DAM 568 COM 3 of 2008 Number Of Colours: 8 for sale

Cup printing machines VAN DAM, MachinePoint has a multicultural team with world presence to be able to be closer to our clients. We speak over 15 different languages.

Data Sheet of Used VAN DAM 568 COM 3

Ref.: 300046823

Year: 2008

Brand: VAN DAM

Delivery time: Immediate

Ask for machine price Want to sell your machine?

Technical Specifications:

- Number Of Colours: 8

- Rim Diameter (Max): 133 mm

- Rim Diameter (Min): 50 mm

- Cup Height (Max): 200 mm

Other Specifications:

Max. printing height: 150 mm

Max. printing length: 400 mm

Min./max. taper: 0 – 15° Max. speed: 400 cups/min.

Other Details:

Guarantee: Without guarantee

Current condition: In Production

Availability: Immediate