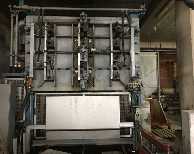

KURTZ - V 1000

EPS pre-expanding. The EPS raw material is conveyed as granules to the pre-expander, where it is heated by means of wet steam. The hot steam softens the polystyrene beads and activates the blowing agent dissolved in them. This evaporates and causes the softened beads ...

2012 | 300047466 | KURTZ