Used Paper bag making machines: WINDMÖLLER & HÖLSCHER Triumph 3 MR/SM/Servo of 2017

Similar Products:

TECON PACKAGE MACHINERY Paper Tuber Machine

Paper bag making machines

Ref: 300046893

TECON PACKAGE MACHINERY

TECON PACKAGE MACHINERY Paper Bottomer Machine

Paper bag making machines

Ref: 300046894

TECON PACKAGE MACHINERY

Data Sheet of Used WINDMÖLLER & HÖLSCHER Triumph 3 MR/SM/Servo

Ref.: 300048155

Brand: WINDMÖLLER & HÖLSCHER

Year: 2017

- Type of bag: Flat handle

Other Specifications:

Block bottom SOS bag making machine designed to manufacture 1 layer paper bags with flat handles

Reel fed

Servo system for the cutting length

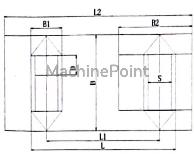

Min-max bag width: 105 – 320 mm

Min-max carrier bags width: 180 – 320 mm

Min-max cut off length: 240 – 650 mm

Min cut off length for carrier bags: 270 mm

Max cut off length for carrier bags including handle: 650 mm

Min-max bottom width: 55-180 mm

Min-max bottom width for carrier bags: 70 – 180 mm

Roll width: 1070 mm

Jumbo Roll Unwind: for rolls up to a diameter of 1.300 mm with motorized lateral adjustment

Automatic precise and continuous web tension control over the entire diameter of the paper roll

Servo motor – driven brake for the paper unwind with suspended dancer roller

Hydraulic reel lift in

1 pneumatic unwind shaft, diameter 76 mm

System for internally glued handles, for the in-line production of paper carrier bags with flat handles:

Slitting unit to obtain broad bottom flaps

Adhesive application nozzles for folded handle strips

Nordson hotmelt application unit for the handles

2 unwind units for the paper handle strips, capable of pivoting to allow a spare roll to be loaded: roll diameter max 1.000 mm core diameter 70 or 76 mm

2 unwind units for the reinforcing patch material with edge guide control, FIFE, accommodated in a separate frame: roll diameter max 1.000 mm, core diameter 70 or 76 mm

Assembly to perforate the web in the handle areas

Gripper cylinders for application of the handle strips

Draw unit for the outer web for adjustment of the web tension

SERVO driven to synchronize the machine speed with the speed of the paper web. All cut-off length (incl. handle) of the bag machine can be processed. With 360 ° adjustment of the unit