AM 8715 CL Tuber and AD 8300 Bottomer for paper cement and building material sacks

Installed in 2017

Machine composed of the next main Units:

Tail end printer FLEXA 820

Tuber AM 8115 CL

Automation TRANSSYSTEMS between tuber and bottomer

Bottomer AD 8300

Glue preparation unit

Slitter Rewinder Longslit 1013

Set of Spareparts

Detail Description of each Unit:

Tail-End Printer FLEXA 820

Web width: mm 1620

Printing width:1320 mm

Print repeat range: mm 450 - 1500

Output speed when equipped with:

doctor chamber inking system: max. m/min 350

Materials to be printed: -Paper gsm 40 - 250 -Inks water based

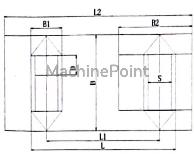

Tuber AM 8115 CL for 3 plies

·Flat tube width min.cm 26

max.cm 60

·Cut-off length, stepped end min.cm 38

max.cm 105

·Cut-off length, flush cut min.cm 32

max.cm 105

·Roll width max.cm 123

·Roll diameter max.cm 130

·Output max.tubes/min.500

·Weight [1]

- without paper, without printer approx.kg 34,000

·Connected load without printer approx. kVA 90 with printer approx. kVA 105

BOTTOMER AD 8300 configured for production of sacks with or without bottom patches

·Sack lengths:

-Stepped end cm 41 - 74

-Flush cut [2] cm 41 - 74

·Bottom widths:

-Stepped end cm 9 - 14

-Flush cut cm 9 - 14 Sack width cm 32 - 55

·Width of opened bottom cm 18 - 34

·Bottom centre distance cm 32 - 60

· Tube lengths cm 54 - 94

·Valve patch:Valve unit, Version 8300

-Cut-off length cm 10 - 22

-Valve length cm 10 - 22

-Roll width cm 10 - 30 Valve unit, Version 8310

-Cut-off length cm 10 - 25

-Valve length cm 10 - 24

-Roll width cm 10 - 30

· Bottom patch: [2]

-Cut-off length cm 18 - 45

-Web width cm 8 - 18

·Output:

-AD 8300 with 2-drum delivery maximum 360 sacks/min

· Packet frequency:

-AD 8300 with 2-drum delivery maximum 28 hands /min

Energy requirements:

-Power consumption kW 65

-Connected load 400 V

-Control voltage 24 V DC

Air (600 kPa) Nm3/h 17

Glue Preparation Plant

-Adhesive preparation unit for cold water soluble starch-based adhesives

-Adhesive preparation unit extension for second adhesive viscosity

- Biozid Metering for precise and safe addition of adhesive preservative

SLITTER REWINDER Longslit 1013

Working width: 1.350 mm

Unwinding roll diameter: max. 1.300 mm

Inner core diameter: max. 76mm

Rewinding roll diameter: 1.300 mm

Inner core diameter: 76mm

Slitting width: min. 25 mm with max. 30knives

Material: Paper 50-200 g/m2

Speed: max. 400 m/min (depending on material)

Electrical requirement: 400 V, 50/60 cycles. 3 phases.

35 kVA

Compressed air requirement: 6-7 bar. 200 NL/min.

motor KW 30