KARVILLE - KV-DSUP-400

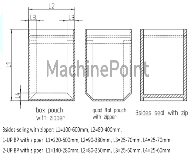

Pouch making machine. Ideal for short-run, high-quality production. Quick changeovers – Tool-less design and recipe memory for fast setup. Low waste – Integrated ramp speed control reduces scrap during startup. User-friendly touchscreen (HMI) – Simple interface with recip...

2019 | 300048776 | KARVILLE