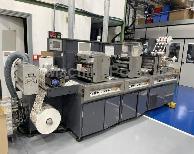

Machine build to work right to left

Web width 330mm

QUIPMENT DESCRIPTION / FEATURES:

Unwind

• 700mm unwind, electronic web guide (edge guide sensor) splice table and web clamps,

auto brake tension control.

• Roll lift for 700mm unwind

• Corona treatment Vetaphone

Infeed nip drive section, infeed dancer.

Semi rotary flexographic printing station with quick change cassette comprising stainless

steel ink pan, pick up roller, ceramic anilox roller and reverse angle doctor blade. The

station has auto pre-positioning and servo drive re-register

• 2 x Coating Cylinder 19” (coating width 320mm)

• 1 x Printing Cylinder 19”

o Flexo plate = 1,70mm

o Tape = 0,20mm

• 1 x Anilox roller 400LPI (6,77cm3/m2)

• 1 x Anilox roller 200LPI (11,8cm3/m2)

• GEW air cooled UV curing unit 140w/cm

• Hot air drying system

Over laminating tower with waste carrier rewind

Mid press dancer to allow full rotary coating

Semi rotary die cutting station with 19” magnetic cylinder (18” maximum repeat).

• Kocher & Beck Gapmaster

Outfeed nip drive section, outfeed dancer.

Waste matrix stripping (maximum diameter 600mm)

Rewind

• Scissor slitting including 5 knives and removable knife shafts

• Back Scorer used for edge trimming the silicon carrier, which is then rewound with the

matrix.

• Single spindle rewind with variable tension control, 76mm air expanding shaft

• label length counter with batch and pause facility

• Second rewind shaft with 76mm shaft

Specification

Maximum web width 330mm

Minimum web width 180mm

Maximum repeat length 18” (457,2mm)

Minimum repeat length 2” (50,8mm)

Rewind max diameter 500mm